Currently Empty: $0,00

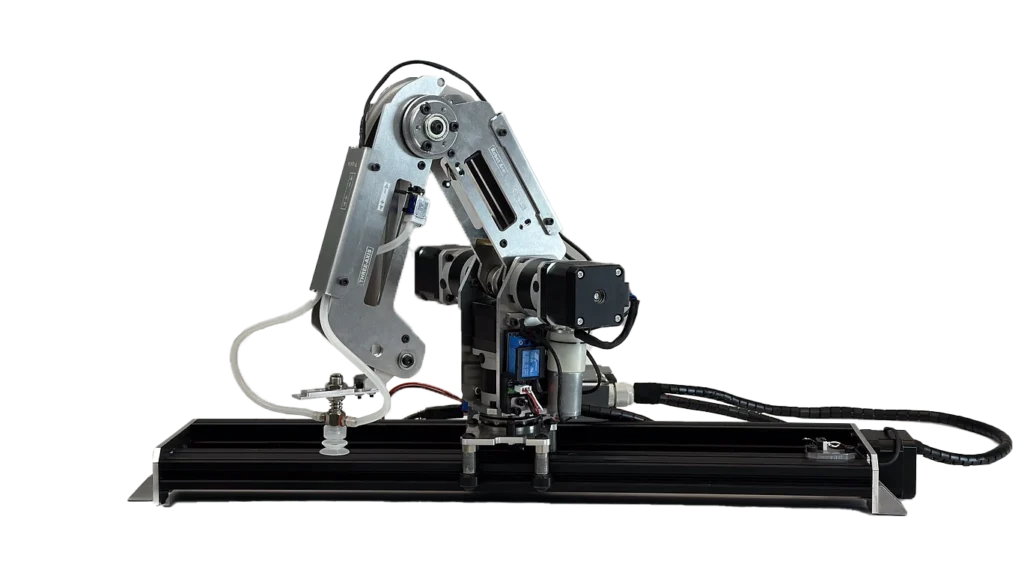

QL-HC10 Collaborative Robot

The QL-HC10 Collaborative Robot is a precision 6-axis cobot with 1200 mm reach, 10 kg payload, and ±0.05 mm repeatability, designed for safe, flexible automation in laboratory, research, and industrial environments.

OVERVIEW

Description

The QL-HC10 Collaborative Robot is an advanced 6-axis collaborative robotic arm. It is engineered for precision industrial automation, laboratory workflows, and research applications. These applications require exceptional repeatability, safety, and operational flexibility. Designed for use in academic institutions, government research facilities, and high-precision manufacturing environments, the QL-HC10 delivers reliable, repeatable motion performance. This performance is especially effective in shared human–robot workspaces.

With an extended working reach of 1200 mm and a robust 10 kg payload capacity, the QL-HC10 supports a wide range of tooling configurations. These include electric and pneumatic grippers, vacuum end-effectors, and custom research fixtures. Its industry-leading ±0.05 mm repeatability ensures consistent accuracy. This accuracy is crucial for demanding applications like metrology workflows, optical component handling, and precision assembly operations.

The system features an intuitive teaching pendant interface. This feature enables rapid programming and deployment without requiring advanced robotics expertise. Integrated collaborative safety functions and electronic emergency stop systems allow safe operation. Furthermore, compliance with modern human–robot interaction standards ensures safety in laboratories and production environments.

An open-architecture controller ensures seamless integration with third-party vision systems, smart cameras, force-torque sensors, and peripheral automation equipment. Full compatibility with RoboDK offline programming software allows users to simulate, optimize, and validate robotic programs. This is done prior to physical deployment, reducing commissioning time and operational risk.

Delivered as a complete, ready-to-deploy solution, the QL-HC10 includes professional documentation, installation flexibility, comprehensive warranty coverage, and long-term technical support.

Technical Highlights

-

Degrees of freedom: 6-axis

-

Maximum reach: 1200 mm

-

Maximum payload: 10 kg

-

Repeatability: ±0.05 mm

-

Mounting options: Floor, wall, or ceiling

-

Power input: 110–240 V AC, 50/60 Hz

-

Environmental rating: IP54 (IP65 optional)

Software & Integration

-

Intuitive teaching pendant for fast programming

-

RoboDK offline programming compatibility

-

Ethernet TCP/IP and Modbus communication support

-

Open controller architecture for third-party peripherals

-

Supports vision systems, force-torque sensors, and conveyor tracking

-

IEC 61131-3 compliant structured text programming for advanced applications

Safety, Installation & Support

-

Collaborative operation mode for human–robot interaction

-

Electronic emergency stop and integrated safety functions

-

Flexible installation configurations for diverse facility layouts

-

Standard package includes controller, pendant, mounting kit, and cables

-

12-month comprehensive warranty

-

Ongoing technical support and application engineering assistance