Currently Empty: $0,00

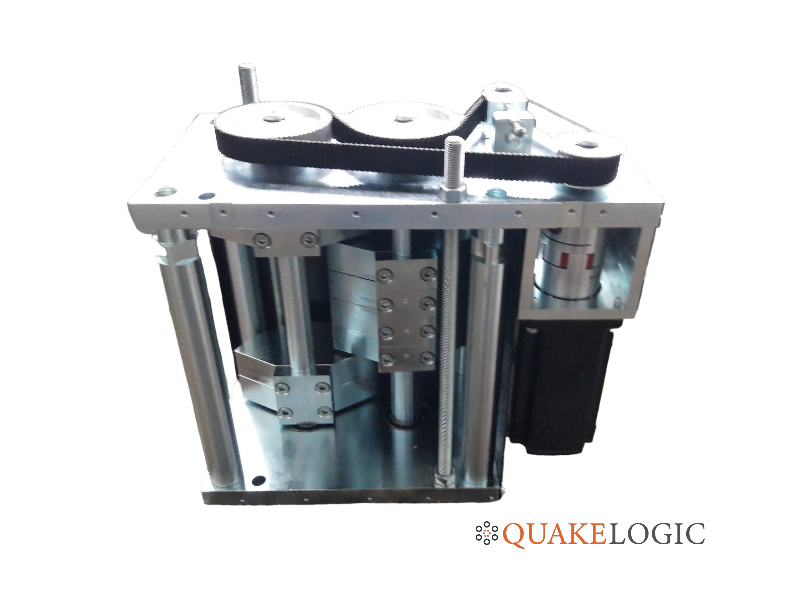

QL-FORTIS 50 Universal Testing Machine

High-precision electromechanical universal testing machine by QuakeLogic. 50 kN capacity, ±1 % accuracy, servo drive, ASTM E4/ISO 7500-1 compliant.

OVERVIEW

Description

Precision Testing for Research, Education & Quality Assurance

The QuakeLogic QL-Fortis 50 (50 kN capacity) is a microcomputer-controlled electromechanical universal testing machine engineered for tension, compression, and flexure testing of metals, composites, plastics, and other materials. Designed for university laboratories, research institutes, and industrial QA facilities, the QL-Fortis 50 combines powerful servo control, advanced data acquisition, and intuitive Windows-based software for fully automated, high-precision material testing.

Built to exceed ASTM E4, E83, ISO 7500-1, and DIN standards, the system delivers ±1 % accuracy, real-time curve plotting, and automated reporting — ensuring reliable and repeatable results across all test modes.

System Components

| Component | Description |

|---|---|

| Load Frame | Dual-column, table-top electromechanical frame with high-rigidity steel structure and precision ball-screw drive |

| Servo Drive System | 3 kW AC servo motor offering high response frequency (2.0 kHz) and low noise operation |

| Load Cells | Interchangeable TEDS load cells (100 N – 50 kN) with ≥ 150 % FS overload protection |

| Crosshead Travel | 1150 mm max |

| Control Accuracy | ≤ ± 1 % of reading |

| Safety Enclosure | Transparent shield with door interlock and emergency-stop pushbutton |

| Computer System | Windows 11 PC (64-bit, 32 GB RAM, dual 512 GB SSD, 27″ LCD monitor) pre-loaded with TestControl software |

🛡️ Warranty & Support

- One-Year Comprehensive Warranty covering all mechanical, electrical, and software components

- Lifetime Remote Technical Support for hardware and software

- Free Software Updates and Firmware Upgrades during warranty period

- Guaranteed spare-part availability and post-warranty service plans

🌍 Why Choose QuakeLogic QL-Fortis 50

✅ Meets or exceeds JSU IFB No. 25-19 requirements

✅ Fully compliant with ASTM E4/E83 and ISO 7500-1 standards

✅ U.S.-based installation and support team

✅ Turnkey solution — delivered, installed, trained, and ready for use

✅ Trusted by leading universities and research labs nationwide

FEATURES

🔍 Key Features

- Force Capacity: 100 N – 50 kN (interchangeable TEDS-enabled load cells)

- Accuracy Class: ± 1 % of indicated value (ASTM E4 compliant)

- Drive System: Maintenance-free AC servo motor with precision pre-loaded ball screws for smooth, low-vibration operation

- Control System: Digital closed-loop controller with auto-zero, auto-gain, and adaptive feedback calibration

- Test Modes: Tension, compression, and flexure with constant rate of load, displacement, or strain control

- Software: QuakeLogic TestControl for real-time graphing, automated analysis, and standard-compliant report generation

- Safety: Dual (overload + overtravel) protection systems with automatic shutdown on specimen failure

- Accessories: Includes tension grips, compression platens (Ø 100 mm), and flexure fixture with quick-change adapters

- Power Requirements: 220 V AC | 60 Hz | 1 kW (single-phase)

SPECIFICATIONS

📏 Technical Specifications

| Parameter | Specification |

|---|---|

| Model | QL-Fortis 50 |

| Rated Force Capacity | 100 N – 50 kN |

| Accuracy Class | ± 1 % (ASTM E4) |

| Crosshead Travel | 1150 mm |

| Test Space Width | 400 mm |

| Speed Range | 0.01 – 500 mm/min |

| Load Measurement Range | 2 % – 100 % FS |

| Noise Level | < 65 dB |

| Power Supply | 1 kW |

| Machine Weight | ≈ 550 kg |

| Dimensions (L×W×H) | 785 × 580 × 1950 mm |

Control System

Advanced Control & Software

The QuakeLogic TestControl Software provides a powerful, user-friendly environment for creating, running, and analyzing tests.

It supports:

- Real-time monitoring of load, displacement, stress-strain, and time curves

- Automatic test report generation (ASTM/ISO/DIN formats)

- Curve comparison and re-analysis tools

- LAN and internet connectivity for data transfer and remote access

- Batch testing and automated sequence execution

Installation & Training

🔧 Installation & Training

Delivered FOB Destination and installed by QuakeLogic factory-trained technicians, including:

- Off-loading, placement, and alignment

- Calibration verification and functional testing

- Comprehensive operator training (minimum 4 hours)

- Manuals, certificates, and maintenance guides provided

Applications

🧪 Applications

- Educational and Research Laboratories

- Aerospace and Automotive Component Testing

- Construction and Civil Material Analysis

- Polymer, Plastic & Composite Testing

- Quality Assurance and Production Control