Currently Empty: $0,00

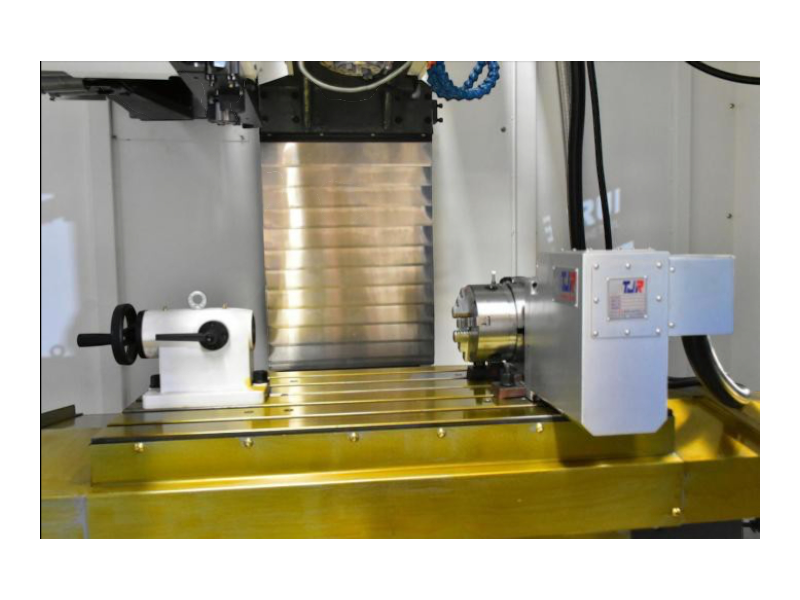

QL-Axis-Compact – 3-Axis Vertical Machining Center

QL-Axis-Compact is a precision 3-axis vertical machining center powered by the Siemens 828D CNC system. It combines strength, speed, and accuracy for metal cutting and high-precision milling. With a BT40 spindle (8000 rpm), Hiwin linear guides, and Renishaw probing, it ensures smooth performance and consistent results. Therefore, it is ideal for aerospace, automotive, and research applications.

OVERVIEW

Description

QL-Axis-Compact is a precision-engineered 3-axis vertical machining center (VMC) built for high-accuracy metal cutting, prototyping, and small- to medium-batch production. It is built on Hiwin linear guideways and powered by a Siemens 828D CNC system, which ensures fast and repeatable performance for demanding machining applications. With its BT40 spindle (8000 rpm), 16-tool ATC, and 5.5 kW main motor, this machine offers reliability, flexibility, and speed.

As a result, it is ideal for aerospace, automotive, precision tooling, and research laboratories.

⚙️ Key Features

-

3-Axis High-Precision Machining – X = 650 mm, Y = 500 mm, Z = 500 mm travel.

-

Powerful BT40 Spindle – Up to 8000 rpm belt-drive for stable cutting performance.

-

Siemens 828D Touch CNC System – Intuitive interface with advanced tool-path control.

-

Hiwin Linear Guideways & C3 Ball Screws – Provide smooth motion with ±0.005 mm accuracy.

-

16-Tool Hat-Type Magazine – Automatic tool changer that speeds up production cycles.

-

Renishaw TS27R Tool Setter & OMP40 Probe – Automates tool and workpiece measurement.

-

Automatic Lubrication & Cooling System – Extends machine life and stabilizes operation.

-

Heavy-Duty Cast-Iron Base & Frame – Offers excellent vibration damping and rigidity.

-

Optional 4th / 5th Axis Rotary Tables – Expand machining capability when needed.

-

Compact Footprint – 4100 × 2250 × 2530 mm, ideal for space-limited workshops.

🧰 Optional Upgrades

-

Automatic chain-type chip conveyor

-

4th and 5th axis rotary tables

-

24-position disc ATC magazine

-

Spindle through-coolant system

-

Oil cooler and water separator

-

Higher-speed spindle (10000 / 12000 rpm)

-

Alternative CNC controls (Fanuc, Mitsubishi, GSK)

🌐 The QuakeLogic Advantage

Engineered for precision and reliability, the QL-Axis-Compact brings together world-class components — Siemens control, Hiwin guides, and Renishaw probing — with our commitment to performance and innovation. Each machine is fully tested for accuracy and delivered ready for production. Therefore, you can start machining with confidence from day one.

SPECIFICATIONS

Technical Specifications

| Specification | Value |

|---|---|

| Table Size | 800 × 400 mm |

| Travel (X/Y/Z) | 650 / 500 / 500 mm |

| Max Worktable Load | 400 kg |

| Spindle Speed | 8000 rpm (10000 / 12000 rpm optional) |

| Spindle Taper | BT40 |

| Main Motor Power | 5.5 kW |

| Rapid Traverse (X/Y/Z) | 24 m/min |

| Feed Rate | 1 – 8000 mm/min |

| Positioning Accuracy | ±0.005 mm |

| Repeat Accuracy | ±0.003 mm |

| Machine Weight | 3800 kg |

| Overall Dimensions |

APPLICATIONS

Applications

-

Precision component manufacturing

-

Aerospace and defense prototyping

-

Automotive tool and die fabrication

-

Research laboratories and universities

-

Small and medium workshops seeking high-accuracy CNC solutions