Currently Empty: $0,00

UNIVERSAL HYDRAULIC TENSILE/BENDING TEST MACHINE, TOUCH SCREEN

The Universal Hydraulic Tensile/Bending Test Machine (600/1000 kN) is a high-performance system for testing the tensile, compression, and bending strength of ferrous materials. With advanced hydraulic grips, digital controls, and optional bending and compression accessories, it ensures precise, fully automated testing for industrial and research applications.

OVERVIEW

Description

UNIVERSAL HYDRAULIC TENSILE/BENDING TEST MACHINE (600/1000 kN CAPACITY)

The Universal Hydraulic Tensile/Bending Test Machine (600/1000 kN capacity) is engineered to accurately assess structural properties—such as yield and tensile strength—of ferrous materials. It supports both tensile and compression testing up to its maximum rated capacity, and bending tests for rebar diameters ranging from 8 mm to 40 mm. Bending apparatus and mandrels, as well as ball seating assemblies for compression tests, are sold separately.

Core Sample Testing

To test core samples up to 100 mm, an upper platen must be ordered separately.

Safety and Performance

- Equipped with a limit switch on the lower grip and safety check valves on the hydraulic system to ensure operational safety.

- Quiet and efficient hydraulic power unit.

Specimen Compatibility

- 600 kN model: Tests 0–40 mm flat and 8–32 mm round samples.

- 1000 kN model: Tests 0–40 mm flat and 8–40 mm round samples.

- Features user-friendly hydraulic jaws built to meet international standards.

Measurement System

- Load measured via high-precision load cell.

- Strain captured using an integrated electronic displacement transducer.

Automation

- Fully automatic testing via digital control unit or computer interface.

- The system automatically returns to start position upon test completion.

- Grip spacing is motor-adjustable using an intuitive handset controller.

- Open-front hydraulic wedge grips allow easy specimen loading.

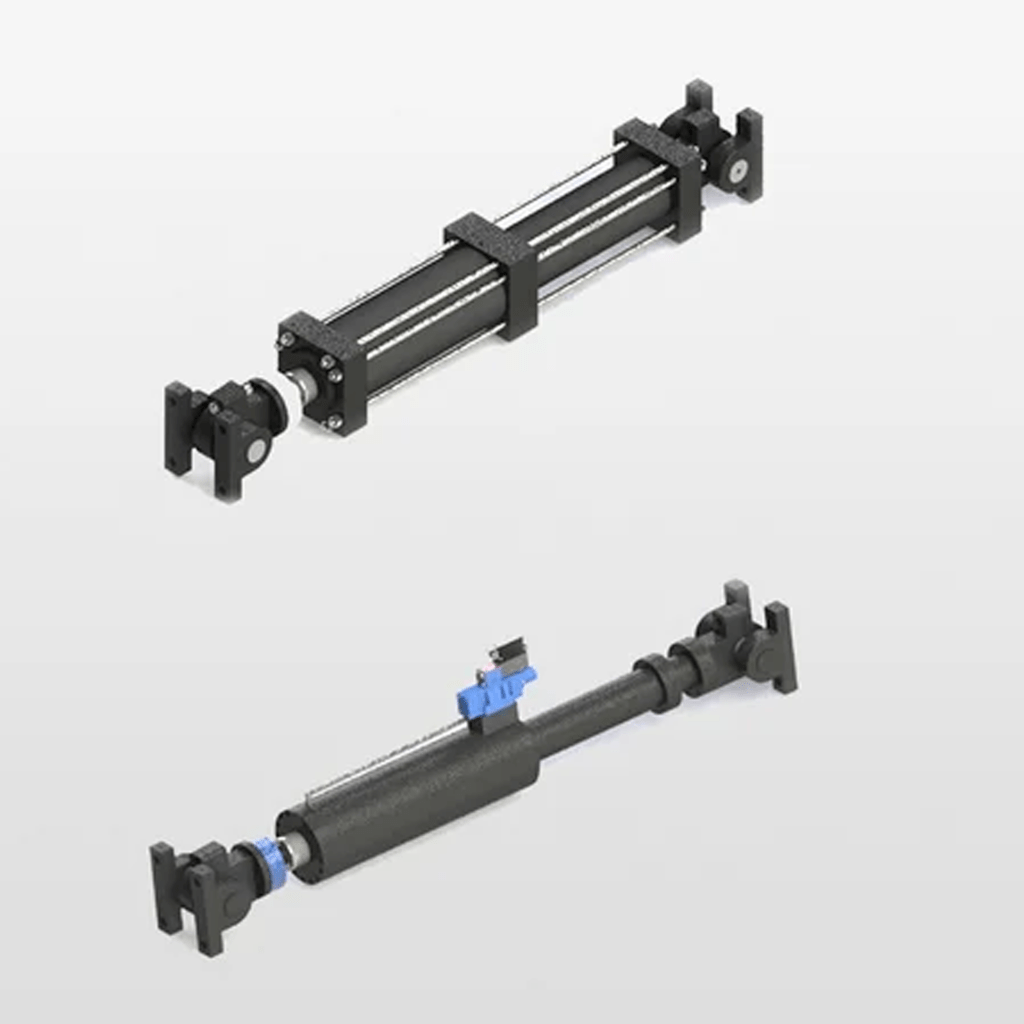

HYDRAULIC GRIPS

- Hydraulically actuated grips eliminate slippage and ensure accurate strain measurement.

- Operated by an independent 400-bar hydraulic power unit.

- 600 kN model includes grips for 8–32 mm round samples.

- 1000 kN model includes grips for 8–40 mm round samples.

- Jaw faces for flat samples must be ordered separately.

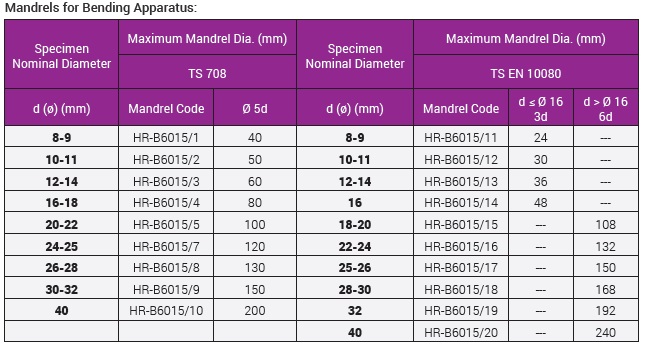

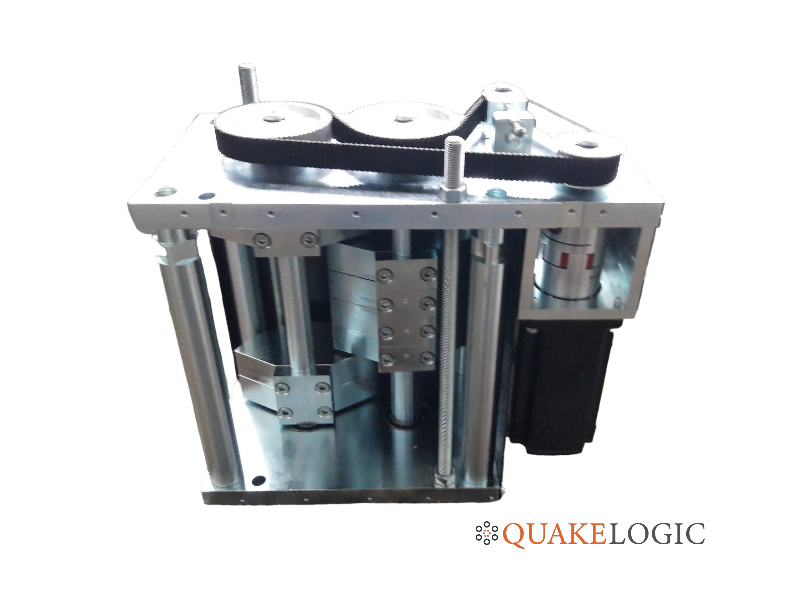

BENDING APPARATUS

- Designed for 8–40 mm rebar diameter testing.

- Compatible with HR-B6000 & HR-B1000 models for Ø8–20 mm rebars.

- Conforms to TS 708 and TS EN 10080 standards with 180° bend testing.

- Apparatus and mandrels are optional add-ons.

HYDRAULIC POWER PACK & H-TOUCH PRO MAX UNIVERSAL CONTROL UNIT

Hydraulic Power Pack Features:

- Silent, variable-speed operation (2 mm/min–18 mm/min ±5%).

- Safety valve protects against overloading.

- Graphical LCD display with intuitive menu navigation.

- Dual pump system: one for grip actuation, one for test load.

Dual Pumps Include:

- Grip pump with dual-stage configuration:

- Low-pressure gear pump for rapid approach.

- High-pressure radial piston pump (400 bar) for secure grip.

- Main piston pump for test loading.

Motor System:

- Main pump driven by AC motor with inverter control.

- Grip pump controlled manually via foot pedal.

- Pressure monitored by 0–600 bar manometers on upper and lower grip connections.

Oil Tank:

- 60 L capacity, visible level/temperature indicators.

- Uses 46-grade hydraulic motor oil.

DIGITAL CONTROL SYSTEM – H-TOUCH PRO MAX

Main Features:

- Load and displacement control

- Real-time graphical display (Load vs. Time / Stress vs. Strain)

- 2 analog channels (load cell / pressure or displacement transducer)

- Integrated thermal printer (optional)

- Adjustable resolution and scaling

- Up to 8-point calibration per channel

- Up to 10,000 test result storage or 80 hours of real-time logging

- 3 selectable unit systems: kN-MPa-mm / lbf-psi-in / kgf-kgf/cm²-cm

- Ethernet and USB ports for data transfer

- Password protection for settings and calibration

Hardware Specs:

- 2 customizable analog channels with 24-bit ADC

- 800×480 resolution TFT-LCD touchscreen (65K colors)

- 33 Hz control loop

- Dual ARM Cortex M3 microprocessors (data acquisition & display)

- USB flash drive support up to 32 GB

- Optional integrated printer

H-GUI UNIVERSAL SOFTWARE

Key Features:

- Free software for machine control and data acquisition

- Supports compression, tensile, and split tensile tests

- Stores and manages test parameters, client/specimen data

- Designed for rebar tensile testing and welded fabric evaluation

- Real-time stress, load, and elongation tracking

- Generates batch reports for up to 42 specimens with standard comparisons

- Language support: English and Turkish

- Exportable results in TXT and Excel formats

- Graphical reports with customizable axes and highlights

- Allows reuse of previous test data and templates

This machine is ideal for academic, industrial, and regulatory laboratories requiring high-precision tensile, compression, and bending testing of metallic specimens. All accessories and optional modules are available upon request.

STANDARDS

EN ISO 15630-1, EN ISO 6892-1, EN ISO 7500-1, TS 708, TS EN 10080

SPECIFICATIONS

_pdf-tablo%201.jpg)

ACCESSORIES/SPARE PARTS