Currently Empty: $0,00

Sheet Metal Cutter

Cutting solution in full swing, making waves in the industry with its groundbreaking simplicity, cost-effectiveness, and ability to produce clean cuts across a diverse spectrum of thicknesses.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

Benefits you can get from OMNI Sheet Metal Fiber Laser Cutting Machine:

- Raycus Laser Power Source 1-6KW

- Working Size(mm): 3000*1500, 4000*1500

- Swiss-Engineered Laser Head

- High Precision Reducer

- Auto Focus System

- Rapid Processing

- High-Precision Gear Rack

- Aerospace Grade Gantry

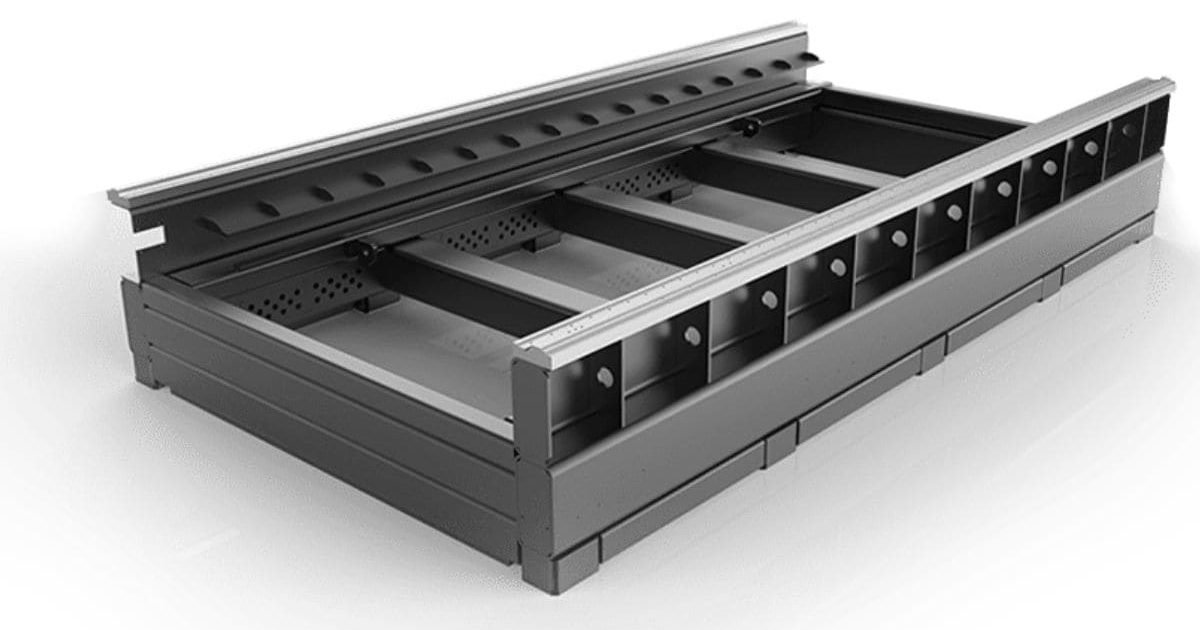

- Sawtooth Blade Cutting Workbed

- Swing-Arm Computer Display

- Cypcut 2000S Software

MATERIAL FIBER LASER SHEET METAL CUTTER

Carbon steel

Stainless steel

Aluminum alloy

Galvanized plate

Electrolytic plate

Silicon steel

Titanium alloy

Aluminum zinc plate

FEATURES OF SHEET METAL LASER CUTTER MACHINE

FRAME

Rigidity: providing a solid foundation for the cutting process.

Stability: Ensuring a stable and accurate cutting experience.

Durability: built to withstand prolonged use and exposure to harsh environments.

Precision: Allowing for consistent and accurate cutting results.

Accessibility: Making maintenance and servicing simple and straightforward.

Enhanced Safety: Minimizing the risk of accidents or injuries during the cutting process.

Improved Efficiency: Resulting in faster production and increased throughput.

Longevity: Providing long-lasting performance and ensuring a high return on investment.

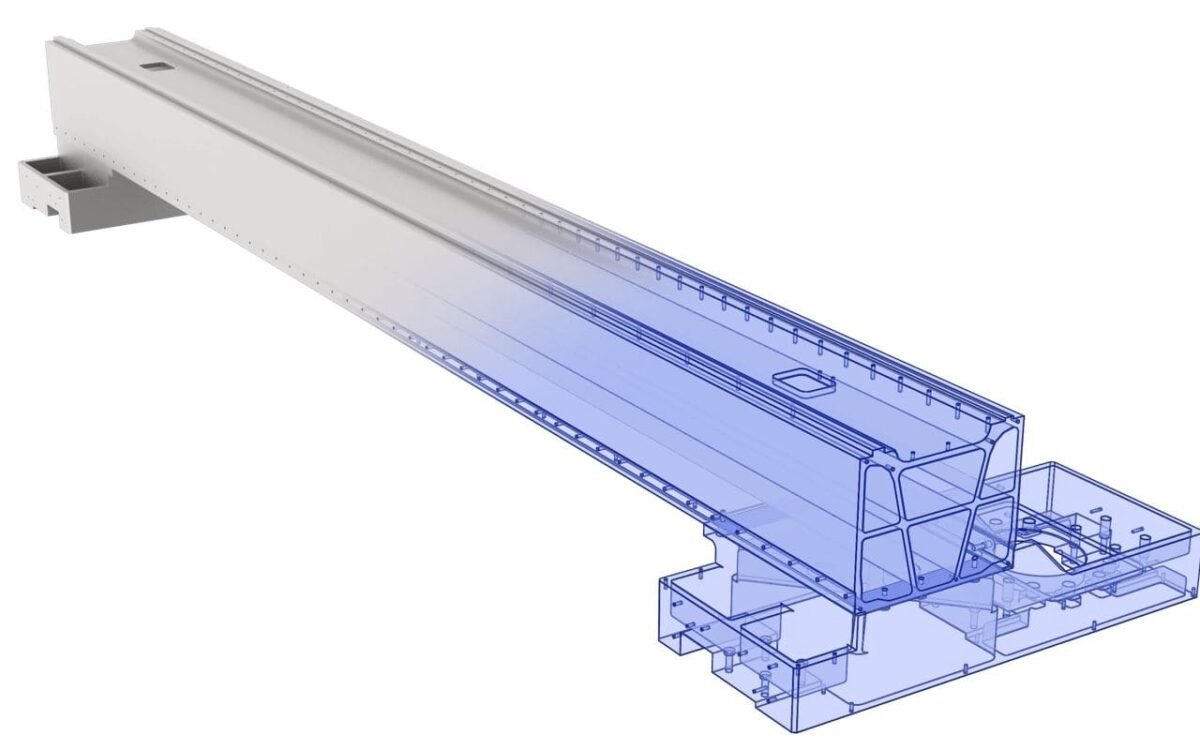

COLD DRAWN EXTRUDED ALUMINUM BEAM

High Strength

Lightweight Construction

Rigidity

Thermal Stability

Low Maintenance

Longevity

Superior Durability

Resistance to Wear and Corrosion

Stable Cutting Process

Consistent Performance

Precise and Accurate Cutting Results

Easy to Move and Transport

SMART COLLISION PREVENTION TECHNOLOGY

Ensures reliable production, minimizing damage to the laser head.

Say goodbye to the laborious and time-consuming manual focusing required to process sheets of different materials and thicknesses.

Auto focus laser head reduces focusing time by 50% by automatically adjusting to the optimal position. This feature even enhances productivity when piercing thick plates.

Lens focus can be adjusted automatically realize automatic perforating and cutting plates of different thickness.

WORLD FAMOUR DRIVING SYSTEM

High Precision for accurate and consistent cutting results.

Increased Cutting Speeds for improved efficiency and higher throughput.

Energy Efficiency to reduce operating costs and environmental impact.

Low Maintenance for minimal downtime and reduced maintenance costs.

Enhanced Safety Features to protect workers and equipment.

User-Friendly Controls for ease of operation and increased productivity.

Consistent Performance for reliable and high-quality cutting results.

Longevity and Durability for a high return on investment and extended machine lifespan.

INTUITIVE FSCUT OPERATING SYSTEM, EQUIPPED WITH TOUCH SCREEN

Streamlines the laser cutting process, thereby enhancing the overall user experience.

The user-friendly interface, coupled with robust compatibility and processing capabilities, ensures seamless operations.

The integration of CAD, Nesting, and CAM modules into a single platform enables users to initiate the metal processing workflow with a few clicks, thereby facilitating the entire process from drawing to workpiece cutting.

INDUSTRIES IN FIELD

- Metal cutting,

- Electrical switch manufacturing,

- Aerospace

- Food equipment

- Textile equipment

- Engineering machinery

- Locomotive manufacturing

- Household appliances manufacturing,

- Tool processing,

- Petroleum machinery manufacturing,

- Metal Fabrication

- Agricultural and forestry machinery

- Elevator manufacturing

- Special automobiles

Parameters

| Model No. | OMNI3015A | OMNI4020A |

| Working Area | 1500mm * 3000mm (4.92‘ * 9.84‘) | 2000mm * 4000mm (6.56‘ * 13.1‘) |

| Laser Power | 1000W – 6000W Raycus (Optional IPG) | 1000W-6000W Racycus ( IPG Optional) |

| Laser Wave Length | 1064nm | 1064nm |

| Working Table | sawtooth | 1064nm |

| Maximum Cutting Speed | 660mm/s | 660mm/s |

| Repeatability | ±0.03mm | ±0.03mm |

| Max. Rapid Travel Speed | 20m/ min | 20m/ min |

| Max. Acceleration | 1g | 1g |

| Drive System | Yaskawa Servo Motor & Drive ( Leadshine Optional) | Yaskawa Servo Motor & Drive ( Leadshine Optional) |

| Control System | FSCUT2000 | FSCUT2000 |

| Table Max. Load | 700KG | 900KG |

| Auxiliary Gas | oxygen,nitrogen,air | oxygen,nitrogen,air |

| File Format | plt, dxf, ai | plt, dxf, ai |

| Metal Safety Cover | Optional | Optional |

| Shuttle Table | Optional | Optional |

| Working Voltage | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ, 3PH | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ, 3PH |

| Power Protection Level | IP54 | IP54 |