Currently Empty: $0,00

S100B MINI Pipe Inspection Robot

The industry’s first integrated trolley case design, easy to carry

OVERVIEW

Description

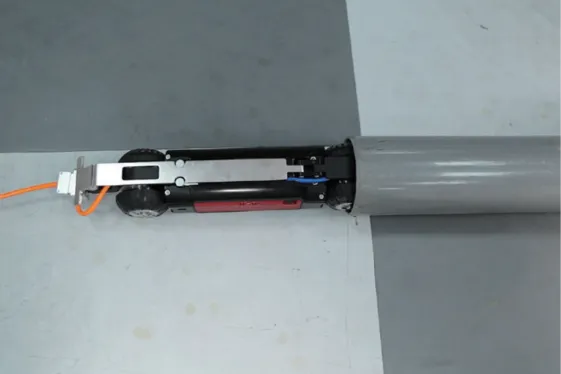

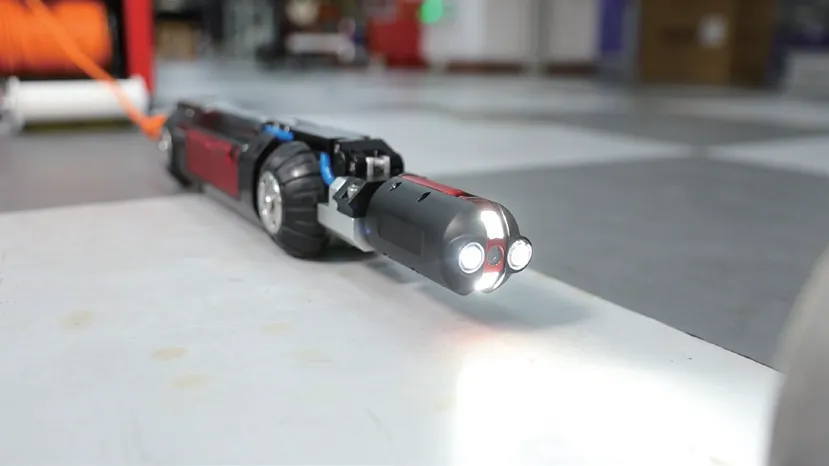

S100B is a portable MINI pipeline inspection robot that can inspect pipelines as small as DN100.

It mainly replaces manual inspection for small pipelines, such as small community pipelines, bridge tunnel pipelines and other hidden and limited spaces for real-time image inspection.

The S100B has an adjustable lifting frame design, direct drive by a hub motor, high efficiency and energy saving, saving manpower and effort, efficient and convenient, and only one person is needed to complete the operation.

- DN100 Minimum detectable

- 210W Digital HD camera

- 50mm Lifting height

- 8kg Robot weight

Technical Parameters

| Scope of application | DN100mm-1200mm |

|---|---|

| Controller Type | Portable tablet termina |

| Obstacle surmounting ability | Not less than 30° |

| Protection level | IP68 |

| Camera unit | Front 210W pixel digital HD camera, 360° axial and 180° radial rotation |

| Drive | Four motor drive, powerful power |

| Zoom | 3× optical as standard, 10× digital as optional |

| Reeling method | Automatic or manual wire reeling and unreeling, automatic wire arrangement |

| Lifting frame | Yes,the lens can be easily raised 50mm |

| Cables | Standard 80m |

| Positioning | With high-precision GPS positioning system, real-time positioning |

| Meter counting method | Absolute encoder, real-time distance display |

| illumination | Main light 2x1W Auxiliary light 2×1W |

| Anti-rollover design | Superimposed wheel hub and built-in anti-rollover software alarm function, real-time animation simulation to display the crawler’s posture inside the pipeline (front and rear tilt angle, left and right tilt angle, lifting platform height) |

| Width measurement | optional laser width measurement function |

| Defogging | Optional one-button defog function |

Application scenario cases