Currently Empty: $0,00

ROBOT

Laser Welding Robot is with high precision welding, be used in a wide range of industries, including sheet metal welding, kitchen utensils, bathroom, hardware, automotive, aerospace and medical sectors.

OMNI provides excellent speed and precision for all types of demanding arc welding and thermal cutting applications, supporting welding and cutting.

Due to high payload, the robot can control laser heads with outstanding performance.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

The six-axis robot is perfect for robotic laser welding welding.

With a high payload of up to 20 kg and a wide working range of 2,010 mm this robot is well suited for industrial welding device, process and larger workpieces. The bended arm design and hollow arm structure allows integrated torch cabling and avoids collisions.

Laser Welding Robot Head

Wobble Welding function

Saving 30% power up than other laser welding head.

Reducing bubbles, frying points, splashes for plates with large impurities.

Reaching up to 0.5mm for welding gap, but othere only can reach to 0.2mm

7 Welding Mode

Dot & Line: strong penetrating power, suitable to penetration welding, stitch welding, or thicker materials.

Circular: adjustable diameter , the energy density is uniform, suitable to thin metal welding (minimum 0.3mm).

Double O, ellipse, triangle, eight characters, semicircle.

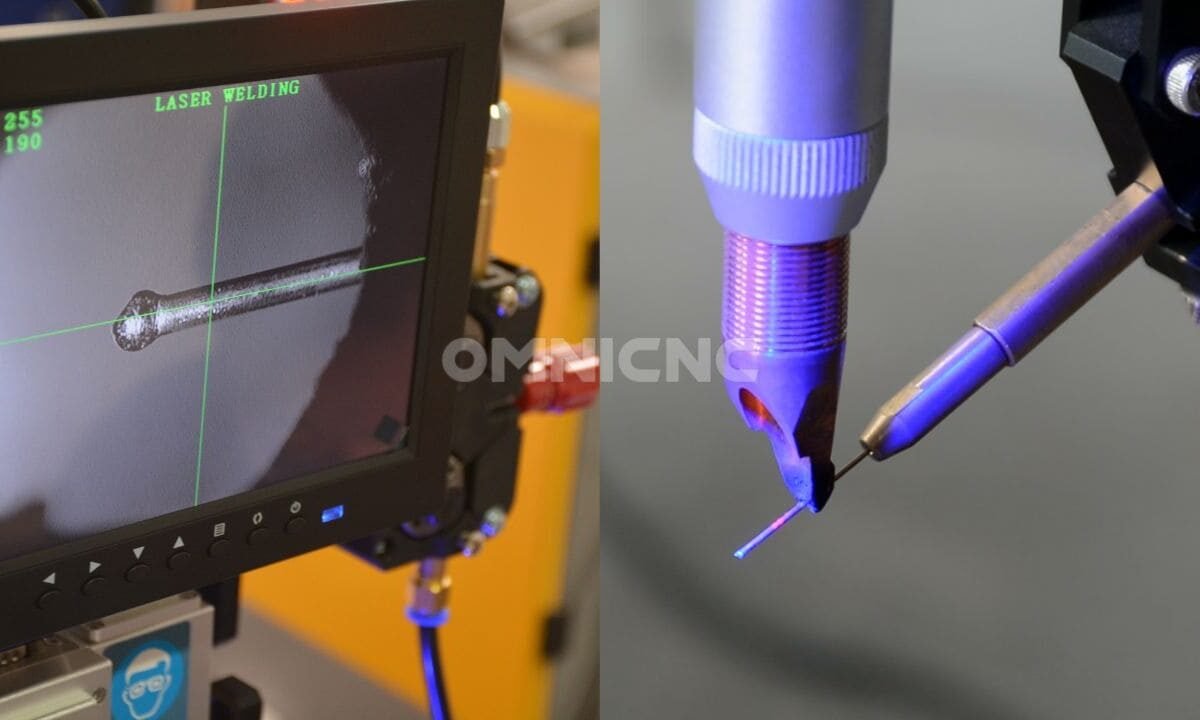

Welding Path Tracking Vision Monitor

Tracking the welding quality with large screen. Easy to notice the issue without staring at the welding point.

Robotic Laser Welder WIRE FEEDER

With wire feeder device, the welding wire can be feeded manually and automatically.

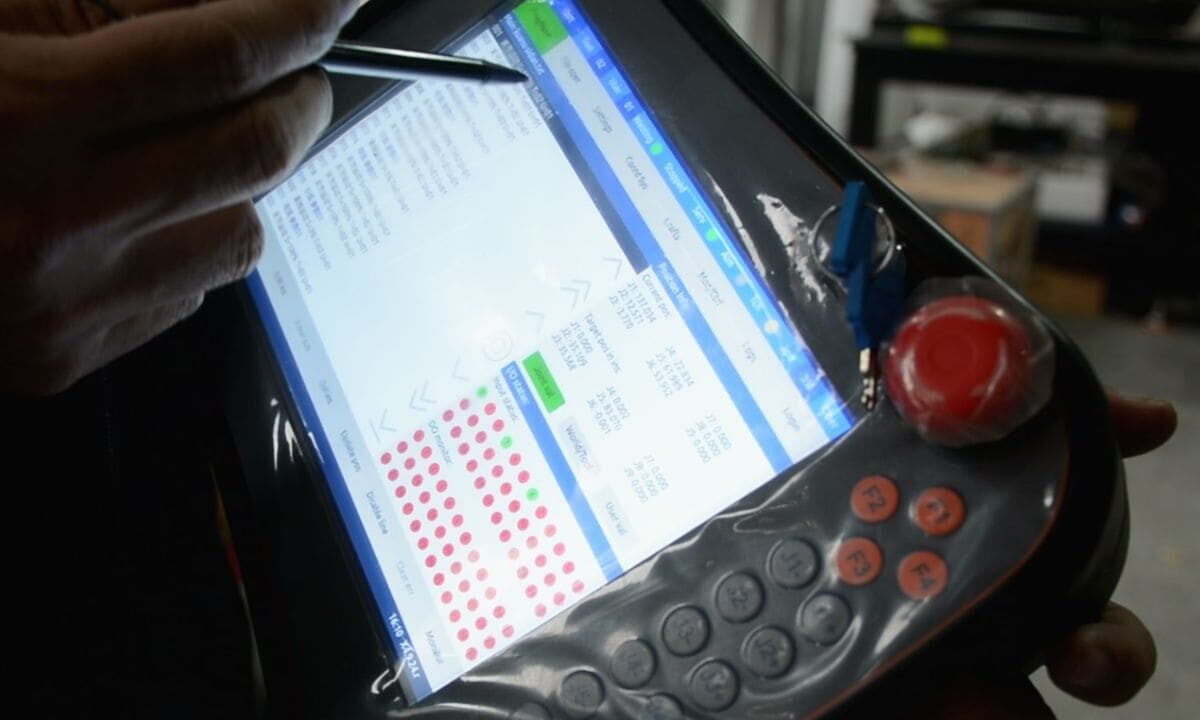

TEACH PENDANT

Control the robot motion and laser beam

Guide the robot and workpiece coordinate and motion path

Set and edit program

Program file management

PROTECTION GLASSES

Always wear protection glasses when you face at the laser beam.

WHY LASER WELDING ROBOT

Precise, Cleaner Seam, Low Thermal Distortion

Create deep and accurate welds with much less energy than traditional welding way.

More cleaner welds and require far less touch-up or rework.

Distortion is minimized regardless of the type of metal welding.

Low Circumstance Requirements,Fine Weld

Can be welded at room temperature or under special conditions.

Can be welded in vacuum, air and a certain gas environment.

Can be welded through glass or materials that are transparent to the beam.

Automation, Easy Operation

Simple and easy to write and edit program, user-friendly.

Multiple motion mode for fast and high precision welding result.

High Laser Energy, Possible for Refractory

High laser power destiny. The welding aspect ratio can reach up to 5:1, and Max. 10:1.

Can weld refractory like titanium, quartz, etc., and can weld heterogeneous materials.

Complex Welding Position Be Accesible

The complex welding positions can be accessed by laser welding robot.

The laser welder perform non-contact remote welding with great flexibility.

Reliable, Stable, Low Maintenance

Qualified, stable, and ultra-high photoelectric conversion efficiency.

Long lifetime and can work continuously for more than 80,000 hours

Parameters

| Specification | Details |

|---|---|

| Model & Robot | OMNI Turin2690 |

| Payload | 20kg |

| Max Working Radius | 1921mm |

| Laser Power | 2KW |

| DOF | 6 Axis |

| Weight | 220kg |

| Motor & Drive | RRRobotica |

| Rated Power | 4.7kW |

| Max Speed | J1 187°/s, J2 148°/s, J3 169°/s, J4 234°/s, J5 225°/s, J6 360°/s |

| Max Operation Area | J1 ±160°, J2 150°~-90°, J3 80°~-100°, J4 ±150°, J5 ±110°, J6 ±300° |

| Protective Specification | 54 |

| Position Repeat Accuracy | ±0.05mm |

| Voltage | 380V 3PH / 220V 3PH / 410V 3PH |