Currently Empty: $0,00

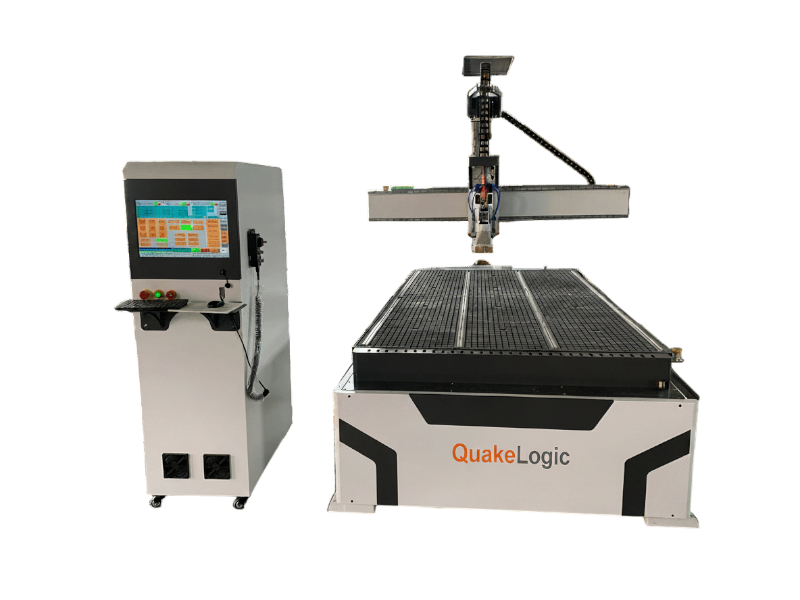

QL-Atlas 4×8 Pro ATC – Industrial CNC Router System

Instruction-grade, industrial CNC router with full 4×8 working area, automatic tool changer (ATC), closed-loop servo motion system, and advanced CNC control. Engineered for education, workforce training, and continuous industrial operation.

OVERVIEW

Description

The QL-Atlas 4×8 Pro ATC is an instruction-grade, industrial CNC router system. It is designed for full-sheet machining, high precision, and continuous operation in educational, training, and professional fabrication environments.

Featuring a full 4 ft × 8 ft working envelope, the system enables complete sheet processing without repositioning. This minimizes material waste and maximizes productivity. A high-power variable-speed spindle, closed-loop servo motors on all axes, and precision linear guide rails deliver exceptional accuracy. They ensure repeatability and smooth motion across demanding applications.

The integrated Automatic Tool Changer (ATC) with a minimum 6-position tool magazine supports complex, multi-step machining workflows. It reduces setup time and improves instructional efficiency. An industrial vacuum table with sectional control ensures secure work-holding for both full sheets and small parts. This eliminates the need for mechanical clamps.

Optimized for instructional use, the advanced CNC control system features an intuitive graphical interface alongside professional-level programming capabilities. The system is compatible with all major CAD/CAM platforms, including Mozaik, Microvellum, Cabinet Vision, and KCD Software.

Delivered as a turnkey solution, the QL-Atlas 4×8 Pro ATC includes professional installation and on-site operator training. It also offers manufacturer-backed warranty coverage, providing long-term reliability. You can rely on it for safety and performance in modern manufacturing programs.

Technical Specifications

-

Working Area: Full 4 ft × 8 ft (48 in × 96 in)

-

Z-Axis Travel: Exceeds 3.75 in

-

Motion System: Linear guide rails, ball screw drives, closed-loop servo motors

-

Positioning Accuracy: ±0.005 in or better

-

Repeatability: ±0.003 in or better

-

Automatic Tool Changer: Minimum 6-position ATC

-

Materials Supported: Wood, composites, plastics, acrylics, aluminum, non-ferrous metals

-

Dust Collection: Minimum 4-inch port compatibility

Software & Control

-

Intuitive CNC control interface optimized for education

-

Real-time toolpath simulation and verification

-

Multi-level user access control

-

Production monitoring and reporting

-

Automatic backup and recovery

-

Remote diagnostics capability

-

Compatible with all major CAD/CAM platforms

Delivery, Training & Support

-

FOB Destination delivery with freight prepaid

-

Professional installation, calibration, and commissioning

-

Minimum 24 hours of on-site operator training

-

1-year manufacturer warranty covering parts, labor, and technical support

-

Minimum 10-year parts availability commitment

-

Ongoing technical and application support