Currently Empty: $0,00

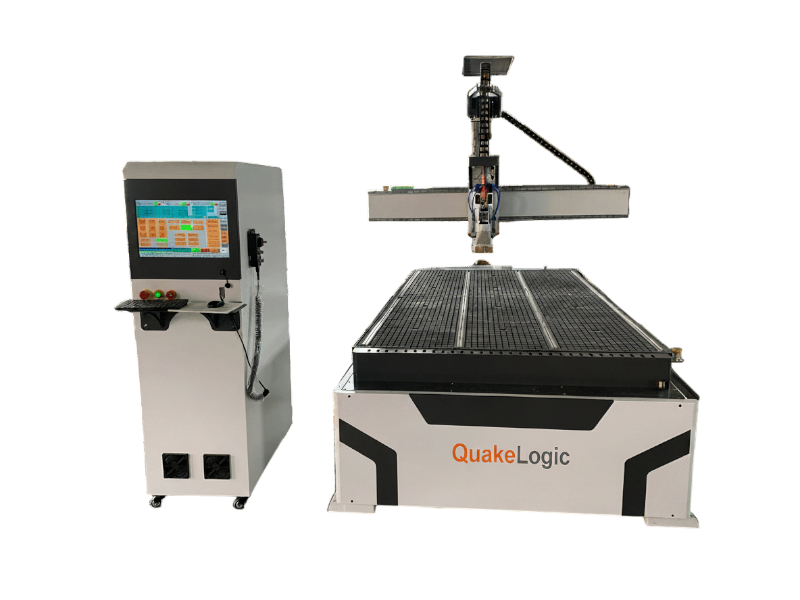

QL-RouteMaster EDU-Pro – Educational 48″ × 96″ CNC Router System

The QL-RouteMaster EDU-Pro is a safety-certified, educational-grade 48″ × 96″ CNC router system engineered for secondary schools, STEM labs, and technical education programs. Featuring a 3.0 kW high-speed spindle, precision linear motion system, VCarve Pro compatibility, and full classroom safety integration, it delivers industrial-level performance in a student-focused design.

OVERVIEW

Description

Built for Education, Not Just Industry

The QL-RouteMaster EDU-Pro is a 48″ × 96″ CNC router made specifically for schools and training labs. It serves as a leading Educational 48×96 CNC Router System designed to meet the needs of educators and students alike. Unlike industrial machines, this system focuses on classroom safety and ease of use. As a result, instructors can confidently introduce CNC manufacturing in supervised environments.

Key Benefits

First, the system provides a full-sheet cutting area while keeping a practical footprint. In addition, the rigid frame supports stable daily use. Therefore, performance remains consistent throughout the school year, making the Educational 48×96 CNC Router System ideal for ongoing academic projects.

-

Full-sheet cutting area: 48″ × 96″

-

3.0 kW spindle with 6,000–18,000 RPM

-

Compatible with wood, plastics, composites, and soft metals

-

High accuracy and repeatable results

-

USB and Ethernet file transfer options

Precision and Performance

Moreover, the EDU-Pro delivers smooth motion and reliable cutting paths. Because of this, students can produce clean and accurate parts. At the same time, fast travel speeds help complete projects within class periods. The Educational 48×96 CNC Router System is recognised for its precision performance in school environments. Consequently, instructors can manage time more effectively.

Software and Workflow

The control system supports manual jog, file storage, and feed/speed override. In addition, it works seamlessly with VCarve and VCarve Pro. Therefore, students can move from design to production without complex setup steps. In fact, with an Educational 48×96 CNC Router System, students have access to a simplified workflow.

Safety for Classroom Use

Most importantly, safety remains a priority. For this reason, the system includes a latching emergency stop and travel limits on all axes. Furthermore, the enclosed control cabinet reduces exposure to electrical components. In addition, the dust collection interface supports cleaner air in indoor labs. As a result, the machine fits well in educational settings. To sum up, the Educational 48×96 CNC Router System is engineered for safe integration in classrooms.

Power and Installation

Finally, the system operates on 120V or 220V single-phase power. Therefore, most institutions can install it without major facility changes. Overall, the QL-RouteMaster EDU-Pro delivers professional CNC capability in a safe and structured educational format.

Technical Specifications

Working Envelope & Capacity

-

Cutting Area: 48″ × 96″ (1,219 × 2,438 mm)

-

Z-Axis Travel: ≥ 6″ (150 mm)

-

Table Type: T-slot or vacuum-ready spoilboard

-

Maximum Workpiece Load: ≥ 150 kg distributed

Spindle System

-

Spindle Power: 3.0 kW minimum

-

Speed Range: 6,000 – 18,000 RPM

-

Collet Type: ER20 precision system

-

Cooling: Air-cooled, maintenance-free

-

Runout Accuracy: ≤ 0.01 mm

Motion Performance

-

Rapid Traverse: ≥ 15 m/min

-

Cutting Feed Rate: ≥ 10 m/min

-

Positioning Accuracy: ±0.05 mm

-

Repeatability: ±0.03 mm

Control & Connectivity

-

Industrial DSP or PC-based controller

-

Manual jog control

-

Program execution & storage

-

Feed/speed override

-

Diagnostics & fault protection

-

USB and/or Ethernet connectivity

-

Fully compatible with VCarve & VCarve Pro (configured post-processor included)

Safety & Educational Features

Integrated Safety Systems

-

Latching emergency stop with manual reset

-

Software and hardware travel limits on all axes

-

Enclosed dust-protected control cabinet

-

Integrated dust collection interface

Classroom Optimization

-

Noise Level ≤ 75 dB(A) at operator position

-

Designed for supervised educational environments

-

Clearly defined safe operating zones

-

Instructor-focused training documentation included

Compliance

-

Designed in accordance with OSHA

-

ANSI aligned safety practices

-

Recognized electrical safety standards

Delivery, Installation & Warranty

Turnkey Delivery

-

Professional delivery and on-site positioning

-

System commissioning and calibration

-

Performance verification

Training

-

Comprehensive instructor hands-on training

-

Operation & maintenance guidance

-

Safety protocol training

-

Curriculum integration support

Warranty & Support

-

Mechanical and electrical system warranty

-

Motion and control system coverage

-

Technical assistance during warranty period

-

Long-term service and parts availability