Currently Empty: $0,00

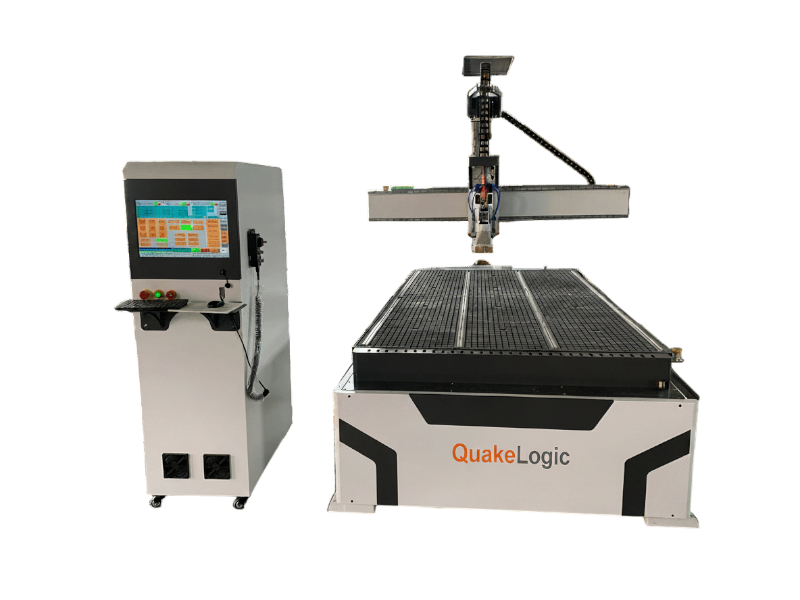

QL-RouteMaster ATC CNC Router Cutting System

A production-grade CNC router with integrated 12-position automatic tool changer, high-speed motion platform, and full-surface vacuum table. Built for repeatable, high-throughput sheet processing with automated probing, dust control, and turnkey installation/training.

OVERVIEW

Description

The QL-RouteMaster ATC is a heavy-duty CNC router cutting system engineered for reliable, repeatable routing performance across demanding production environments. Designed for precision sheet processing and multi-piece runs, its optimized mechanical structure and servo control architecture help maintain stable accuracy during continuous operation—reducing thermal drift and deflection for consistent results across the full working envelope.

QL-RouteMaster-ATC-CNC-Router-C…

Built for large-format production and speed

With a minimum effective cutting area of ≥ 60 in × 140 in, Z-axis clearance ≥ 5 in, and performance designed for ≥ 1200 in/min sustained cutting feed rate and ≥ 2300 in/min rapid traverse, the system supports both prototyping and production workflows where cycle time and dimensional control matter. Positioning repeatability is specified at ±0.005 in or better across the full envelope.

QL-RouteMaster-ATC-CNC-Router-C…

Integrated ATC productivity (12-position carousel)

The integrated 12-position rotary carousel automatic tool changer reduces manual intervention and enables complex multi-tool sequences. A ≥ 13 HP ATC spindle provides routing power for demanding applications, paired with HSK63 compatibility and ER40 collet support to accommodate a wide tool diameter range.

QL-RouteMaster-ATC-CNC-Router-C…

Workholding, dust control, and automation to reduce setup variability

The QL-RouteMaster ATC integrates production-focused subsystems to minimize setup errors and operator variability:

-

Full-surface vacuum table with controllable zones for reliable sheet hold-down

-

Precision locator pins for fast, repeatable alignment

-

Programmable dust boot and industrial dust collection package (≥ 6 HP) for cleaner operation

-

Surface probe & tool sensor for automated Z referencing and tool measurement

-

Automatic calibration for consistent axis referencing and repeatable startups

QL-RouteMaster-ATC-CNC-Router-C…

Turnkey delivery package

Delivered as a complete operational package, the system includes an integrated operator station, crosshair laser pointer, and an integrated 30 KVA transformer (480V → 380V, 3-phase) (as specified in the referenced requirement). The package includes FOB destination delivery, on-site installation & commissioning, and a comprehensive operator training program. Technical documentation and support coverage are included.

Specifications

-

Work area: ≥ 60 in × 140 in effective cutting area

-

Z-axis clearance: ≥ 5 in

-

Sustained cutting speed: ≥ 1200 in/min

-

Rapid traverse: ≥ 2300 in/min

-

Repeatability: ±0.005 in or better

-

ATC: 12-position rotary carousel

-

Spindle power: ≥ 13 HP

-

Tooling interfaces: HSK63 compatible, ER40 collets

Workholding & Automation

-

Full-surface vacuum tabletop with controllable zones

-

Precision locator pins for repeatable squaring/alignment

-

CNC-controlled programmable dust boot

-

Industrial dust collection package (≥ 6 HP)

-

Surface probe & tool sensor for automated setup and tool measurement

-

Automatic calibration for consistent axis referencing

Delivery, Installation & Support

-

Integrated CNC operator station

-

Crosshair laser pointer for alignment/offset verification

-

Integrated 30 KVA transformer (480V → 380V, 3-phase)

-

FOB destination insured freight

-

On-site installation & commissioning (leveling, calibration, functional testing)

-

On-site operator training + documentation and technical support