Currently Empty: $0,00

QL-REDWELD-WS200 – Welding Simulator

Compact VR welding simulator supporting SMAW, MIG/MAG, TIG, and FCAW, with real-time analysis, defect detection, and instructor-controlled evaluation in a portable design.

OVERVIEW

Description

QL-REDWELD-WS200 is a compact, portable virtual reality welding simulator. It is designed to deliver professional-level welding training in environments where space, mobility, and flexibility are critical.

Despite its compact form factor, QL-REDWELD-WS200 supports a full range of industrial welding processes. These include SMAW, GMAW, GTAW (TIG), and FCAW. The system uses real-weight welding torches and a Meta Quest 3 VR welding helmet. As a result, it ensures realistic handling, posture, and technique development.

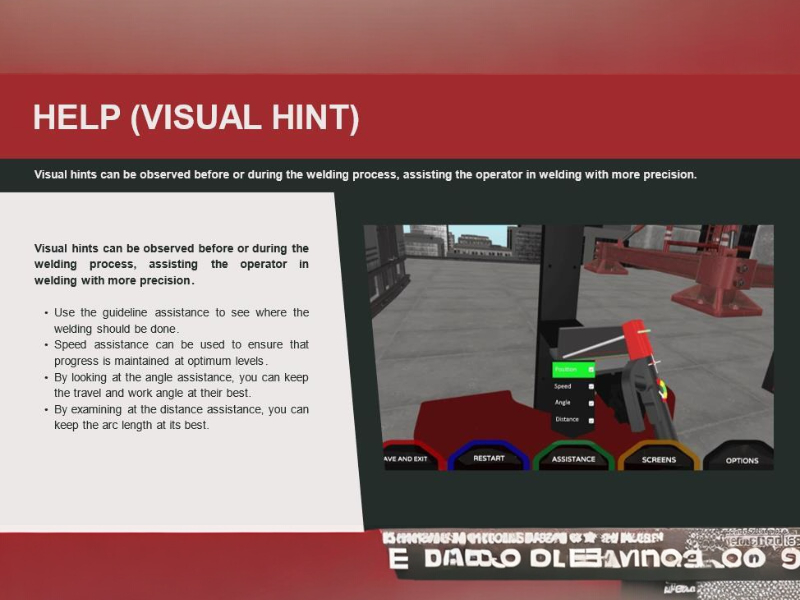

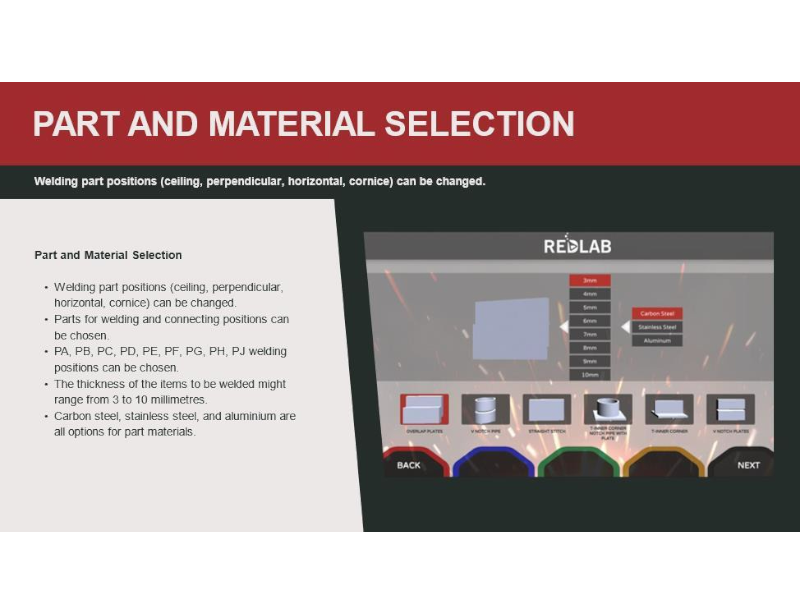

The simulator offers extensive training coverage with PA–6G welding positions, multiple joint types, and adjustable material thickness (3–10 mm). Material selection includes carbon steel, stainless steel, and aluminum. In addition, real-time visual guidance and parameter monitoring track key welding variables. These variables include travel speed, arc length, work angle, travel angle, and nozzle distance.

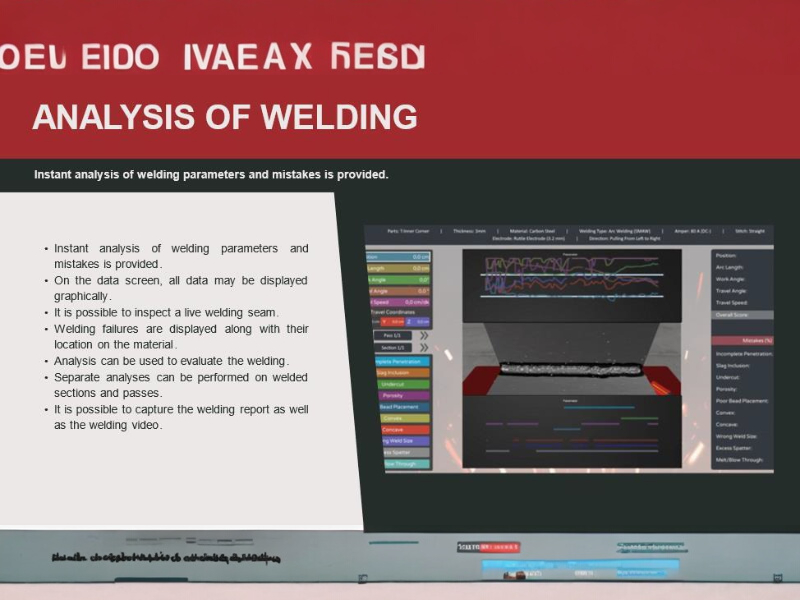

QL-REDWELD-WS200 includes an advanced User Evaluation and Teacher System that records sessions, analyzes welding errors, and generates PDF reports. It also allows instructors to remotely monitor, assess, and compare user performance. By eliminating consumables, fumes, and safety risks, the system provides cost-effective and safe welding training aligned with real-world standards.

Key Features & Capabilities

-

Compact and portable design (30 kg)

-

Virtual reality welding with Meta Quest 3 headset

-

Supports SMAW, GMAW, GTAW (TIG), and FCAW

-

Wide range of welding positions (PA–6G)

-

Real-weight arc, MIG/MAG, and TIG welding torches

-

Real-time visual hints and welding parameter tracking

-

Welding defect detection and performance scoring

-

Session recording, replay, and PDF report export

-

Instructor/Teacher software with remote monitoring

-

Right- and left-handed user support

-

Multi-language interface (English, Turkish, Spanish, German)

Training Scenarios & Applications

Training Capabilities:

-

Plate, pipe, T-joint, butt joint, and overlay welding

-

Carbon steel, stainless steel, and aluminum materials

-

Adjustable thickness from 3 to 10 mm

-

Flat, zig-zag, circular, and multi-pass weld seams

Applications:

Vocational training centers, mobile training labs, technical schools, workforce development programs, industrial onboarding training, and compact classroom environments.