Currently Empty: $0,00

QL-REDWELD-WS100 – Welding Simulator

Professional VR welding simulator supporting SMAW, MIG/MAG, TIG, and FCAW, with real-time analysis, defect detection, and instructor-controlled training and evaluation.

OVERVIEW

Description

QL-REDWELD-WS100 is a professional virtual reality–based welding simulator designed for advanced welding training and skills assessment. You can also use it for certification preparation in vocational, industrial, and educational environments.

The system supports multiple welding processes including SMAW, GMAW, GTAW (TIG), and FCAW. It includes realistic real-weight welding torches and a VR-based welding helmet powered by Meta Quest 3. In addition, a wide range of welding positions (PA–PF/PG, 1G–6G, flat, horizontal, vertical, overhead) and joint types are available. This enables comprehensive training across industry-standard applications.

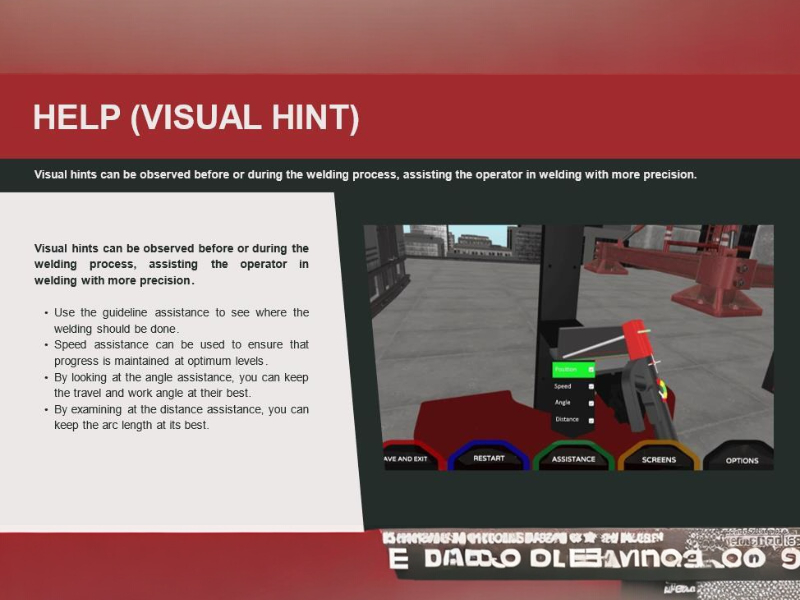

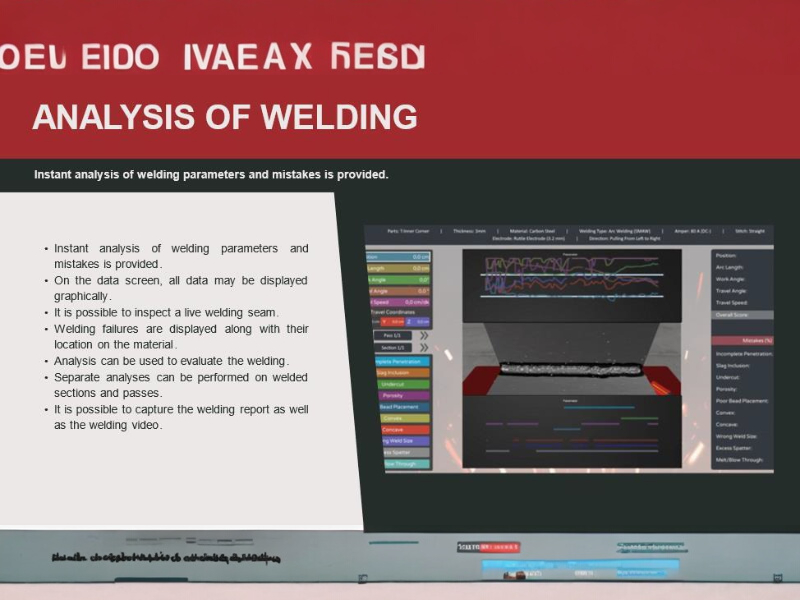

QL-REDWELD-WS100 provides real-time visual guidance, parameter monitoring, and performance scoring. Critical welding parameters such as travel speed, arc length, work angle, travel angle, and nozzle distance are continuously analyzed. The system detects and reports common welding defects including porosity, undercut, slag inclusion, insufficient penetration, excessive spatter, and burn-through.

All welding sessions can be recorded, replayed, and analyzed through the integrated User Evaluation and Teacher System. Instructors can remotely monitor students, access detailed reports, compare user performance, and conduct theoretical exams. The simulator eliminates material waste and safety risks while delivering highly realistic welding training aligned with real-world practices.

Key Features & Capabilities

-

Virtual reality welding with Meta Quest 3 headset

-

Supports SMAW, GMAW, GTAW (TIG), and FCAW processes

-

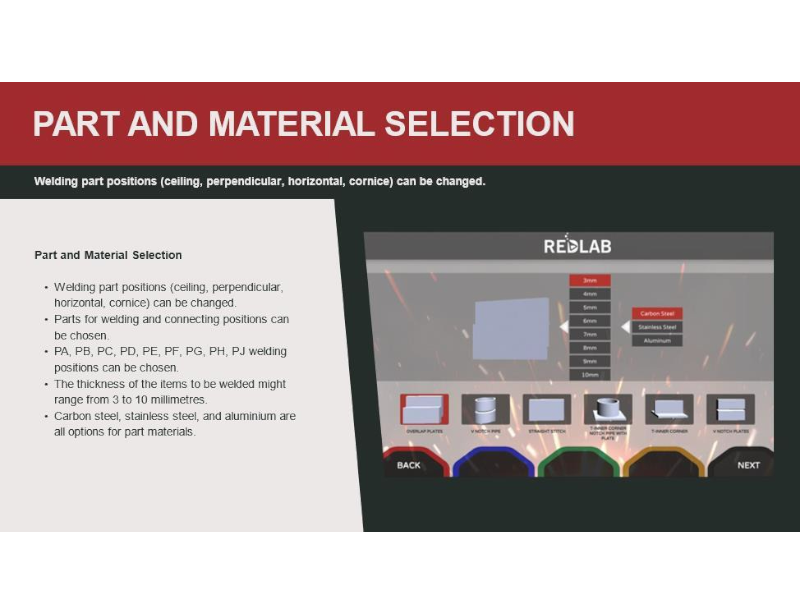

Wide range of welding positions (PA–6G) and joint types

-

Real-weight arc, MIG/MAG, and TIG welding torches

-

Real-time visual hints and parameter tracking

-

Welding defect detection and detailed error analysis

-

Session recording, replay, and PDF report generation

-

Instructor/Teacher software with remote monitoring

-

Right- and left-handed user support

-

Multi-language interface (English, Turkish, Spanish, German)

Training Scenarios & Applications

Training Capabilities:

-

Plate, pipe, T-joint, butt joint, and overlay welding

-

Carbon steel, stainless steel, and aluminum materials

-

Adjustable thickness (3–10 mm)

-

Flat, zig-zag, circular, and multi-pass welding seams

Applications:

Vocational welding schools, technical colleges, industrial training centers, shipyards, construction training facilities, and workforce development programs.