Currently Empty: $0,00

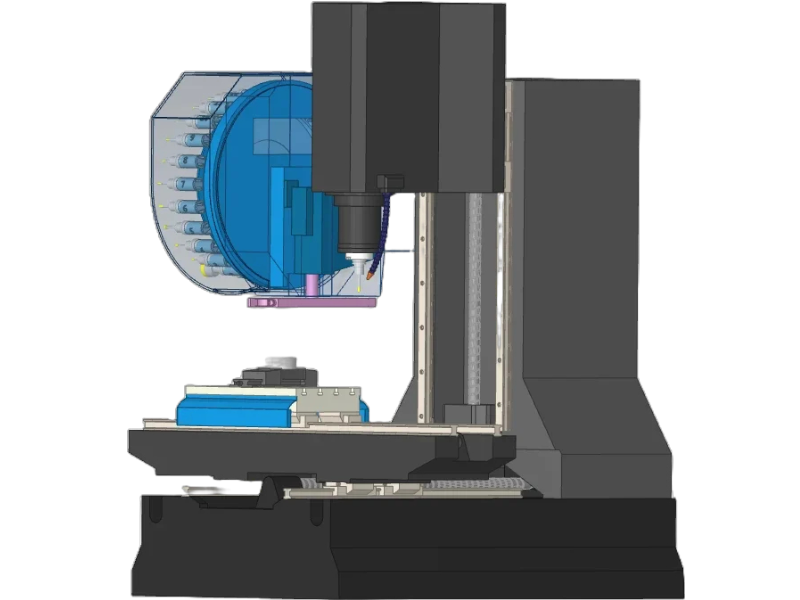

QL-LinearWire 650 Pro

Mission-ready, industrial Wire EDM machine engineered for government, defense, and precision manufacturing. Featuring AC-servo motion control, multi-axis interpolation, high cutting accuracy, and turnkey delivery with full training and support.

OVERVIEW

Description

The QL-LinearWire 650 Pro is an industrial-grade, mission-ready Wire Electrical Discharge Machining (EDM) system. It is engineered to meet the rigorous demands of government, defense, and high-precision manufacturing environments.

Built on a heavy-duty welded steel frame, the system delivers superior vibration damping, structural rigidity, and long-term geometric stability. This is maintained under continuous operation. A fully integrated AC servo-driven motion system operates across all axes (X/Y/Z/U/V). It is combined with precision ball screw drives, ensuring exceptional positioning accuracy, repeatability, and smooth multi-axis motion.

The QL-LinearWire 650 Pro supports simultaneous multi-axis interpolation. This enables the production of complex geometries and tapered features. These features are required for advanced tooling, aerospace, and defense components. Its advanced pulse generator and adaptive control technology provide stable cutting performance. It ensures consistent surface finish across a wide range of conductive materials.

Designed as a turnkey solution, the system includes professional installation, acceptance testing, and comprehensive on-site operator training. Additionally, it provides industry-leading warranty coverage. With long-term parts availability and U.S.-based technical support, the QL-LinearWire 650 Pro delivers reliable, secure, and precision-focused EDM performance throughout its operational lifecycle.

Technical Specifications

-

-

Machine Type: Industrial Wire EDM

-

Motion System: AC servo drives on all axes (X/Y/Z/U/V)

-

Axis Travels:

-

X: 650 mm

-

Y: 500 mm

-

Z: 480 mm

-

U/V: ±60 mm taper adjustment

-

-

Maximum Workpiece Thickness: 200 mm

-

Maximum Workpiece Weight: 600 kg

-

Maximum Taper: ±10° at 200 mm thickness

-

Wire System: Automatic wire threading with servo-controlled tension

-

Dielectric Filtration: Multi-stage filtration to 5 microns

-

Control, Software & Safety

-

Industrial CNC control with English-language interface

-

Closed-loop control with pitch-error compensation

-

Compatible with Mastercam and industry-standard CAD/CAM platforms

-

Ethernet (LAN), USB, and keyboard connectivity

-

Electrical Compliance:

-

UL 508A

-

NFPA 79

-

OSHA 29 CFR 1910

-

-

Safety Features:

-

Dual emergency stop circuits

-

Overtravel, overload, and wire-break protection

-

Full guarding and interlocks

-

Delivery, Training & Support

-

Turnkey delivery, installation, and commissioning

-

Full verification and acceptance testing

-

On-site operator training for government personnel

-

Complete operator, maintenance, and safety documentation

-

12-month full-system warranty (parts, labor, travel)

-

Minimum 10-year spare parts availability

-

Lifetime remote diagnostics and U.S.-based technical support