Description

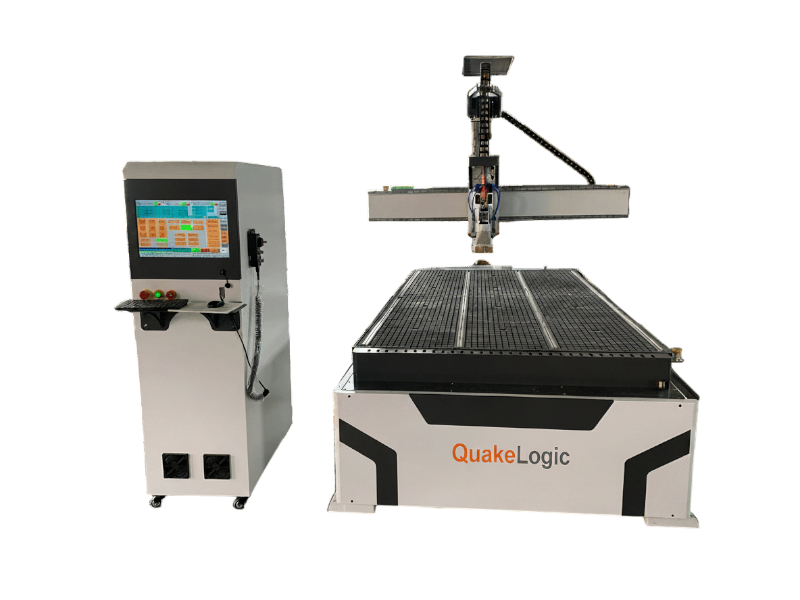

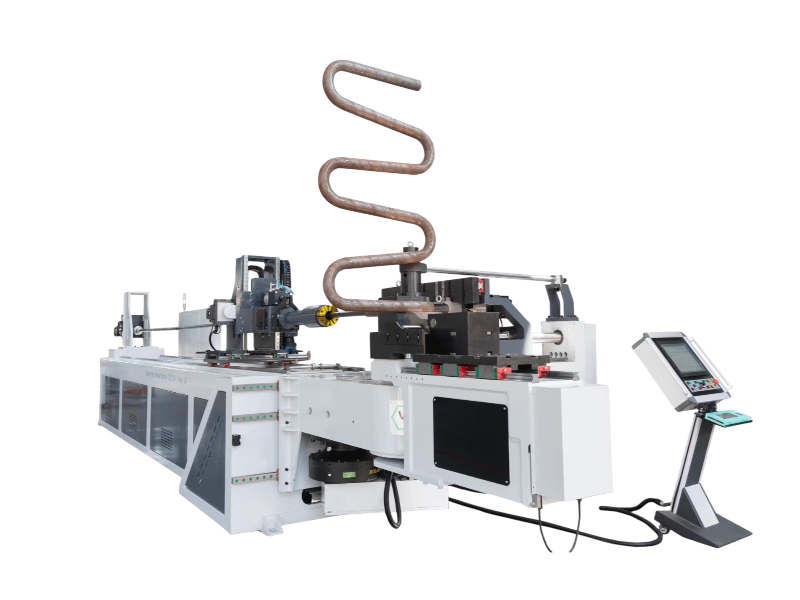

QL-LinearWire 400 is an industrial-grade CNC Wire Electrical Discharge Machining (Wire EDM) system engineered to deliver production-level performance in universities, research laboratories, and advanced manufacturing training centers.

Designed with a fully enclosed machining environment and high-precision multi-axis CNC motion control, the system ensures safe, stable, and repeatable machining operations. Using non-contact wire EDM technology, it precisely cuts **all electrically conductive materials—regardless of hardness—**while achieving excellent dimensional accuracy, fine surface finishes, and consistent reproducibility for research and instructional applications.

The QL-LinearWire 400 uniquely bridges the gap between educational demonstration equipment and full production machinery, allowing students, researchers, and engineers to work with authentic industrial technology while benefiting from an intuitive, safety-focused interface suitable for supervised laboratory environments.

Engineered for long-term laboratory use, the system features a rigid industrial frame, precision motion components, automated wire handling, and optimized process controls that support complex geometries, materials research, prototype fabrication, and advanced process development.

Delivered as a complete turnkey solution, each system includes:

- Professional installation and placement

- System commissioning and calibration

- Operator training and operational documentation

- Starter consumables package

- One-year comprehensive warranty

- Ongoing technical support and service coordination

As a result, the QL-LinearWire 400 is an ideal solution for universities, technical institutes, research facilities, and training centers seeking to modernize their precision manufacturing capabilities with safe, reliable, and industry-relevant Wire EDM technology.

Key Features

Key Features — QL-LinearWire 400 CNC Wire EDM System

-

Industrial-Grade CNC Wire EDM Platform designed for academic, research, and advanced manufacturing environments

-

Fully Enclosed Machining Chamber ensuring operator safety and dielectric containment

-

High-Precision Multi-Axis CNC Control (XYZUV) for complex geometry and contour machining

-

Non-Contact Wire EDM Technology enabling precision cutting of all electrically conductive materials regardless of hardness

-

Excellent Dimensional Accuracy & Repeatability suitable for research and precision component fabrication

-

Stable Kerf Control & Fine Surface Finish for high-quality machining outcomes

-

Rigid Industrial Machine Frame for long-term stability and vibration reduction

-

Automated Wire Handling & Tension Control improving reliability and reducing setup time

-

Adaptive High-Frequency EDM Power Supply for consistent machining performance

-

Integrated CNC Controller with CAD/CAM Compatibility supporting DWG/DXF import and G-code workflows

-

Research-Ready Configuration supporting materials research, prototype fabrication, and process development

-

Closed-Loop Dielectric & Filtration System for stable cooling and extended fluid life

-

4-Axis Simultaneous Cutting Capability (X, Y, U, V) for tapered and complex profile machining

-

Optional Rotary Axis Capability for multi-sided machining in a single setup

-

Turnkey Delivery Package including installation, commissioning, training, and documentation

-

One-Year Comprehensive Warranty & Technical Support

Applications

Applications — QL-LinearWire 400 CNC Wire EDM System

-

Precision Component Manufacturing for complex and high-tolerance mechanical parts

-

Academic Instruction & Manufacturing Training in universities and technical colleges

-

Research & Development Laboratories conducting materials and machining process studies

-

Prototype Development for aerospace, automotive, and advanced engineering components

-

Tool & Die Manufacturing including punches, dies, molds, and precision tooling inserts

-

Aerospace & Defense Component Fabrication requiring machining of hardened and exotic materials

-

Medical Device & Implant Prototyping requiring fine detail and burr-free machining

-

Materials Science Research including testing of steels, titanium, and advanced alloys

-

Micro-Precision Part Production for electronics, instrumentation, and sensor components

-

Machining of Hardened Materials unsuitable for conventional cutting methods

-

Complex Geometry & Contour Cutting for research prototypes and precision assemblies

-

Fixture & Jig Manufacturing for laboratory and industrial production setups

-

Precision Mold & Insert Manufacturing for plastics and metal forming applications

-

Conductive Material Machining including steel, stainless steel, titanium, copper, and carbide

Technical Highlights

Technical Parameters — QL-LinearWire 400 CNC Wire EDM System

Machine Structure

-

Machine Design: Integrated industrial design

-

Machine Structure: T-type machine body, C-frame construction

-

Machine Dimensions: 1680 × 1200 × 1800 mm

-

Maximum Workpiece Load: 400 kg

-

Worktable Size: 640 × 400 mm

-

Working Table Guard Size: 830 × 600 mm

-

Maximum Z-Axis Travel: 300 mm

-

Maximum Taper (≤100 mm thickness): ±6°

Axis Travel & Motion System

-

X, Y Axis Travel: ≥ 400 × 400 mm

-

U, V Axis Travel: 50 × 50 mm

-

CNC Coordinate System: 5-axis (X, Y, Z, U, V)

-

Coordinate Systems: Machine + 3 user coordinate systems

-

Axis Drive: AC servo motors with precision ball screws and linear guideways

Machining Performance

-

Material Capacity (example Cr12): 20–40 mm

-

Positioning Accuracy: ≤ ±0.005 mm

-

Repeatability: ≤ ±0.003 mm

-

Surface Roughness after multi-cut finishing: ≤ 0.6 µm Ra

-

Maximum Cutting Speed: ≥ 300 mm²/min

-

Maximum Discharge Current: 10 A

Power & Control Configuration

-

High-Frequency EDM System: Low power consumption, non-resistance type

-

Total Machine Power Consumption: < 2 kW

-

Control System: Embedded industrial CNC controller

-

CNC Compatibility: G-code, CAD/CAM, DWG/DXF support

Standard Equipment & Systems

-

Automatic Wire Tensioning System

-

Automated Wire Threading Capability

-

Remote Jog Control

-

Aluminum Cutting Device Included

-

Fine Filtration Dielectric System

-

Closed-loop Coolant System

-

Automatic Lubrication System

Operational Capabilities

-

4-Axis Simultaneous Cutting (X, Y, U, V)

-

Optional Rotary A-Axis Capability

-

Auto-centering & auto-edging functions

-

Adaptive high-frequency EDM control

-

Multi-user coordinate system