Currently Empty: $0,00

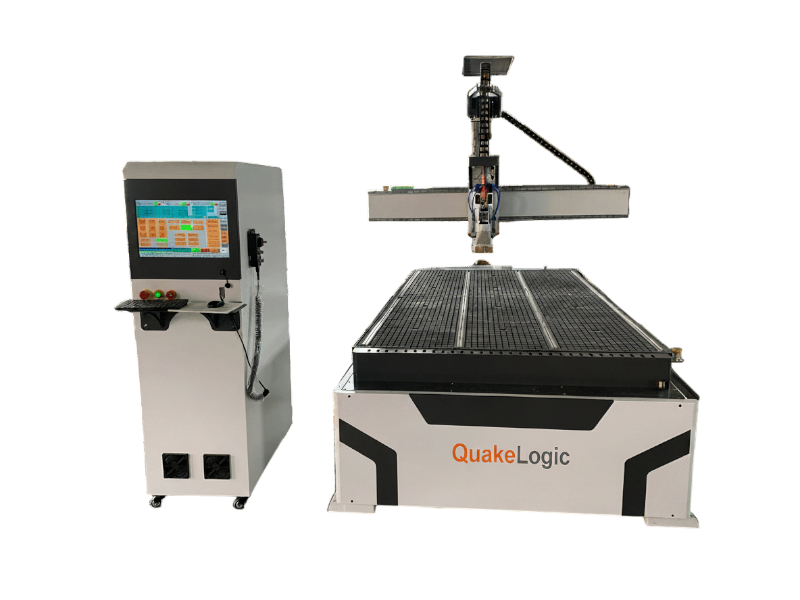

QL-AegisCut 6025 – Defense-Grade CNC Plasma Cutting System

The QL-AegisCut 6025 is a defense-grade CNC plasma cutting system engineered for high-precision metal fabrication in mission-critical environments. Featuring advanced five-axis motion control, a 400A plasma power source, integrated downdraft dust collection, and full solicitation compliance, it delivers uncompromising performance for aerospace, naval, and defense manufacturing facilities.

OVERVIEW

Description

The QL-AegisCut 6025 Defense-Grade CNC Plasma Cutting System represents the pinnacle of heavy-duty plasma cutting technology. It is purpose-built for defense, aerospace, and high-demand industrial fabrication environments.

Designed around a rigid, stress-relieved steel gantry structure, the AegisCut 6025 delivers exceptional dimensional stability and accuracy. It also offers long-term reliability under continuous production conditions. In addition, its advanced five-axis motion architecture enables complex bevel cutting, chamfers, and contoured profiles. The system provides a B-axis bevel range of +45° to −40°. It also includes full ±180° C-axis rotation.

At its core, the system integrates a 400-amp industrial plasma cutting source. This supports both high-speed production cutting and precision marking across a wide range of materials. For example, it includes mild steel, stainless steel, aluminum alloys, and naval-grade armor plate. Additionally, intelligent CNC control with real-time torch height control, kerf compensation, and dynamic feed-rate adjustment ensures consistent cut quality and repeatability.

The AegisCut 6025 is delivered as a fully integrated turnkey solution, including installation, commissioning, operator training, and acceptance support. In addition, comprehensive safety systems, NFPA-compliant dust collection, and secure offline CNC operation make it ideally suited for controlled defense and government facilities.

Engineered for compliance, performance, and operational readiness, the QL-AegisCut 6025 provides a mission-critical capability for modern metal fabrication operations.

Technical Highlights

-

Five-axis CNC torch motion system (X, Y, Z, B, C axes)

-

Cutting envelope: 240” x 100” x 8” (6,096 × 2,540 × 203 mm)

-

B-axis bevel range: +45° to −40°

-

C-axis rotation: ±180° continuous

-

400A plasma cutting and precision marking capability

-

Automatic torch height control with collision protection

-

CNC system with 15” industrial sealed touchscreen

-

CAD/CAM workstation with DXF/DWG import compatibility

Applications & Materials

Applications

-

Defense maintenance and fabrication

-

Aerospace structural components

-

Naval ship repair and metal processing

-

Heavy industrial steel fabrication

-

Precision bevel cutting and weld preparation

Materials

-

Mild steel (ASTM A36, A572, HY-80 / HY-100)

-

Stainless steel (304, 316, duplex grades)

-

Aluminum alloys (5052, 5083, 6061, 7075)

Delivery, Safety & Compliance

-

Turnkey delivery including logistics, installation, and commissioning

-

Integrated downdraft table with automatic airflow control

-

11 kW dust collection system with multi-stage filtration

-

Explosion prevention features compliant with NFPA 484

-

OSHA, ANSI, NFPA, IEC, and NFPA 79 compliance

-

Emergency stops, safety interlocks, and guarded motion axes

-

Comprehensive on-site operator training and documentation