Currently Empty: $0,00

Pro Series

Pro series Industrial ATC CNC Router from OMNI CNC is a powerful and versatile machine that can handle a wide range of CNC routing tasks. Equipped with an automatic tool changer, this machine can quickly and easily switch between cutting tools, improving efficiency and productivity.

Whether you’re a professional woodworker or a manufacturer, the Industrial ATC CNC Router is an excellent choice for your CNC routing needs. Contact us today to learn more about this machine and how it can help take your projects to the next level.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

Excellence in CNC Router Performance at Affordable Cost

The OMNI Carrousel Type ATC and Linear Type ATC CNC Routers are best-sellers because to their outstanding performance and low cost.

The OMNI Pro CNC Router Series meets a wide range of application requirements, particularly in volume-oriented companies that need to handle a variety of sheet widths, individual components, and solid wood products. The OMNI Pro Series qualifies due to its above-average “up-times,” low maintenance requirements, and ease of use.

CNC Router HSD Spindle

The ISO30 9kw frequency spindle on the ATC CNC router has adjustable speeds of up to 18,000 RPM.

Drill Bank is optional.

World Well-Known Controller – Syntec

Provide high-speed, high-precision top-level functions

HPCC high-precision trajectory contour control

smooth processing path

G120.1 multiple sets of machining conditions

Effectively improve the surface finish of machining and improve processing efficiency.

All-Steel Reinforced Gantry

Rigidity has been increased for even higher accuracy. Vibration is reduced, and the longevity and dependability are increased.

High Precision Linear Guide

Linear motion is provided by rack and pinion on the x and y axes, and ball screw drive on the z axis.

On all axes, the OMNI ATC Series CNC Router has 30mm or 25mm 20mm linear rail systems.

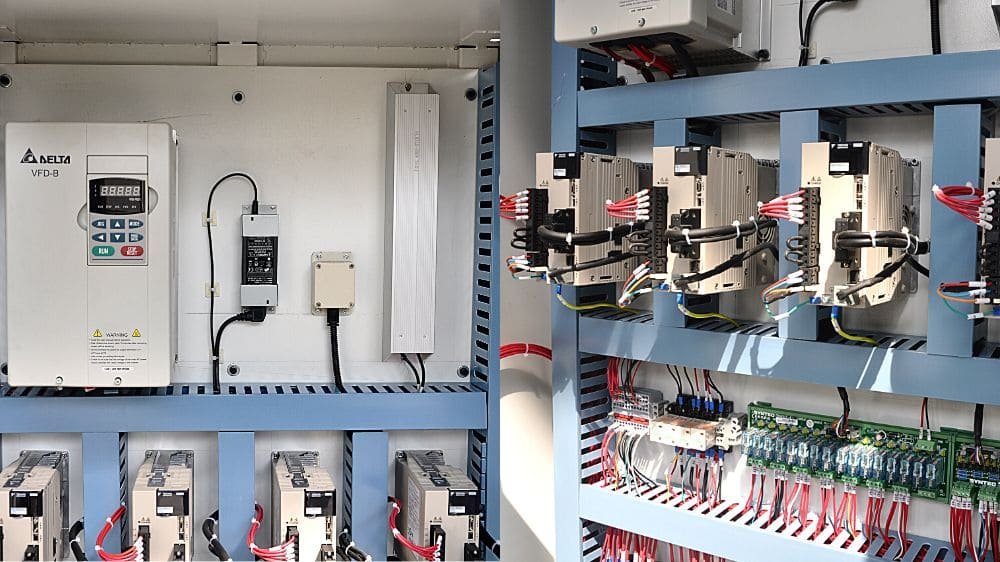

Control Cabinet

European IEC wiring, CE electrical device, and sheethed cable connection.

A double-doored Nema 4 electrical enclosure houses and wires all of the electrical components.

The overall wiring arrangement is labeled so that the client may simply explore the cabinet if servicing is necessary.

COMPATIBLE

OMNI control systems are compatible with Aspire, Vcarve, Fusion360 etc main cnc software.

After the order placed, we will send you the download link of post processor.

Parameters

| Mode No. | OMNI1325Pro, OMNI1530Pro, OMNI2030Pro |

| X, Y-Axis Travel | 1300*2500 ,1500*3000, 2000*3000mm or others |

| Z-Axis Travel | 200mm or more |

| Spindle Power | 9kw HSD Air-cooling Spindle, 18000rpm |

| Repeatability | +/- 0.05mm |

| Max. Rapid Travel Speed | 45m/min |

| Drive System X and Y axis | Rack and Pinion, rail linear bearing |

| Drive System Z axis | Lead Screw, rail linear bearing |

| Standard Work Surface | aluminium T-Plate Extrusion Combined Bakelite Vacuum Table |

| Motor | Servo |

| Working Voltage | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ,3PH |

| Command Language | G Code & M Code |

| Collet | ER32 |

| Tool Change | BT30 ISO30, 8 Positions |

| Operating System | Syntec |