Currently Empty: $0,00

OVERVIEW

Description

Petroleum Safety Training Simulator

The Petroleum Safety Training Simulator provides a realistic VR-based environment for training personnel to handle hazardous materials safely and effectively. By replicating real-world scenarios such as gas leaks, pressure surges, and equipment failures, the simulator prepares trainees for high-risk operations through immersive, controlled practice.

Trainees learn to navigate control room systems, monitor gauges, adjust pressure, and manage gas flow while following strict safety protocols. From initial equipment checks to final inspections, every stage emphasizes accident prevention and proper handling of petroleum products.

The simulator is fully interactive, allowing users to make decisions and see real-time results, enhancing learning and operational readiness.

Enhancing Petroleum Safety Training with SANLAB Learning

Enhancing Petroleum Safety Training and Learning

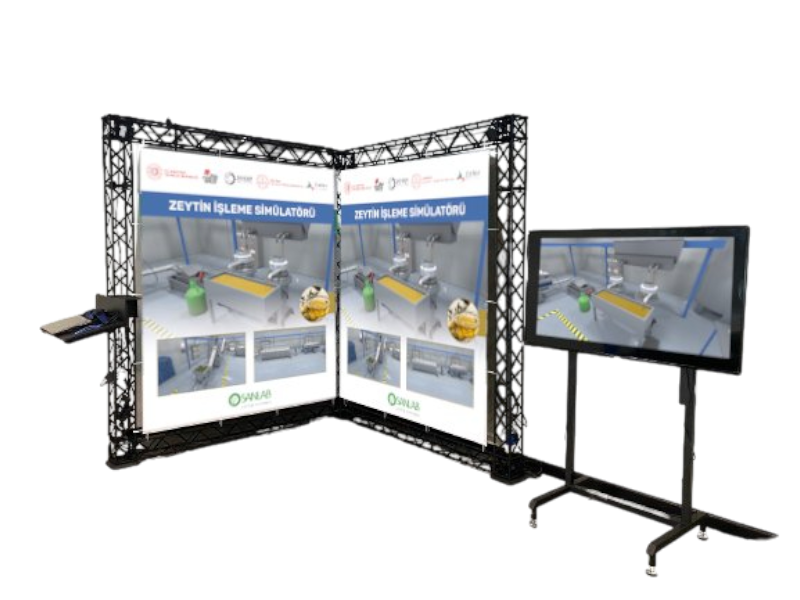

SANLAB’s system combines VR immersion with real-time feedback to deliver safe, cost-effective, and realistic petroleum safety training. Customizable modules, performance tracking, and detailed reporting ensure trainees develop the skills needed for real operational environments.

Comprehensive Training Scenarios

Emergency Response

Simulated incidents such as leaks or equipment failures teach quick and effective response techniques.

Operational Procedures

Covers routine operations including gas filling, pipeline monitoring, and pressure management.

Safety Protocols

Reinforces PPE usage, hazard awareness, and regulatory compliance.

Key Features

Immersive VR Training

Supports devices like Oculus and HTC Vive, allowing trainees to experience full-scale operational environments with enhanced spatial awareness.

Advanced 3D Simulation

Realistic facility models, equipment interaction, and dynamic environmental conditions (e.g., lighting, weather).

Real-Time Feedback

Instant error detection helps users correct mistakes and improve performance. A built-in database tracks progress over multiple sessions.

Environmentally Friendly

Virtual training eliminates material waste and reduces environmental impact.

Core Skills & Scenarios

-

Gas Filling Operations: Safe tank-filling, valve control, emergency shut-offs

-

Leak Detection: Identifying and responding to gas leaks

-

Equipment Handling & Maintenance: Ensuring proper and safe operation

-

Emergency Shutdown: Executing shutdown procedures to minimize risk

Applications

Petroleum & Gas Sector – Training for extraction, refining, and distribution

Chemical Industry – Safe handling of hazardous materials

Education & Training Centers – Preparing students for energy-sector careers

Emergency Response Teams – Practicing crisis management in simulated environments