Currently Empty: $0,00

Eccentric Mass Shaker – Reliable, Realistic Vibration Testing for Every Industry

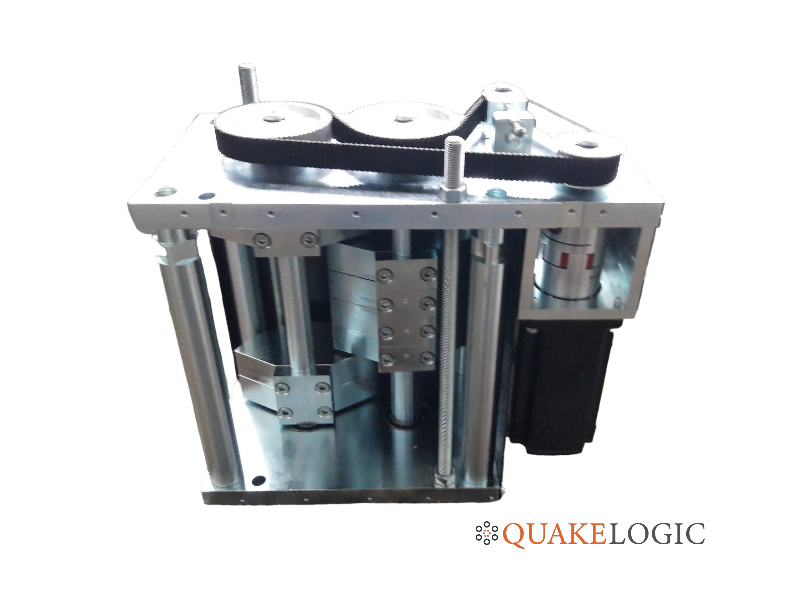

Compact, reliable, and cost-effective, our Eccentric Mass Shakers simulate real-world vibrations to test structural integrity and product durability across industries—ideal for construction, automotive, aerospace, and electronics applications. Custom sizes and capacities available upon request.

OVERVIEW

Description

Precision Vibration Testing You Can Trust

The QuakeLogic Eccentric Mass Shaker is purpose-built for precision vibration and seismic simulation. Designed to replicate real-world conditions with unmatched accuracy, it helps engineers and researchers identify weaknesses, validate safety standards, and optimize structural performance before costly issues arise.

Whether for academic research, product reliability testing, or structural validation, our shakers deliver the accuracy, stability, and durability you expect from a world-class vibration testing system.

Engineered for Durability and Safety Validation

Our servo-driven shakers simulate demanding vibration environments that replicate real operational and seismic forces. This allows engineers to evaluate designs under realistic stress conditions, ensuring compliance with industry safety standards and regulatory requirements.

Applications include:

- Design verification and durability testing

- Prototype validation under seismic or operational vibration

- Product certification and quality assurance

Each system features a Schneider BMH100 servo motor for precision control and a robust mechanical assembly engineered for years of dependable use.

Versatile Applications Across Industries

QuakeLogic’s Eccentric Mass Shakers are trusted worldwide by universities, laboratories, and industrial clients for reliable performance testing. Common applications include:

- Structural testing of buildings, bridges, and infrastructure

- Aerospace and automotive component reliability assessments

- Electronics and machinery performance under vibration

- Research and development in civil, mechanical, and defense engineering

Whether you operate in construction, manufacturing, aerospace, defense, or research, our shakers provide a cost-effective, compact, and scalable vibration testing solution tailored to your needs.

Why Choose QuakeLogic?

✅ Precision Engineering – Servo-controlled motion with repeatable test accuracy

✅ Compact & Durable Design – Built for continuous lab or field use

✅ Scalable Solutions – Custom frequency, size, and force configurations

✅ Expert Support – Lifetime technical assistance and global delivery

Every shaker is designed, tested, and supported by our engineering team — a trusted name in seismic and vibration technologies worldwide.

SPECIFICATIONS

Key Technical Specifications

| Specification | Value |

|---|---|

| Maximum Force Output | 3000 kgf @ 25 Hz |

| Frequency Range | 1–25 Hz |

| Actuator Type | Schneider Servo Motor (BMH100 Series) |

| Max Speed | 3000 rpm |

| Belt–Pulley Ratio | 1/2 – 1/3 |

| Force Axis | Horizontal |

| Power Requirement | 6 kW, 3-phase, 220 VAC |

| Approx. Weight | 106 kg |

| Dimensions | 475 × 250 × 460 mm (L × W × H) |

💡 Configurable options available – from 2 to 8 eccentric disks to vary output force and frequency response.