Currently Empty: $0,00

QL-EduCut X CNC Fiber Laser Cutting System

The QL-EduCut X is a fully enclosed, industrial-grade CNC fiber laser cutting system designed specifically for secondary and post-secondary educational environments. It delivers professional-level cutting performance, advanced safety systems, and hands-on instructional capability—bringing real-world manufacturing technology directly into the classroom.

OVERVIEW

Description

The QL-EduCut X Fiber Laser Cutting System is a classroom-ready, industrial CNC solution. It is engineered to bridge the gap between education and modern manufacturing. The system is built around professional fiber laser technology. Therefore, it enables students to work with the same materials, tolerances, and processes used in today’s fabrication facilities. At the same time, it maintains Class 1 laser safety for instructional environments.

With cutting capabilities of up to 1/2 inch mild steel, 3/8 inch stainless steel, and 3/8 inch aluminum, the QL-EduCut X supports a wide range of fabrication and welding curriculum applications. Automatic focus and height control systems ensure consistent cut quality and minimal dross formation. Additionally, they provide controlled kerf width across the full 5′ × 10′ cutting bed.

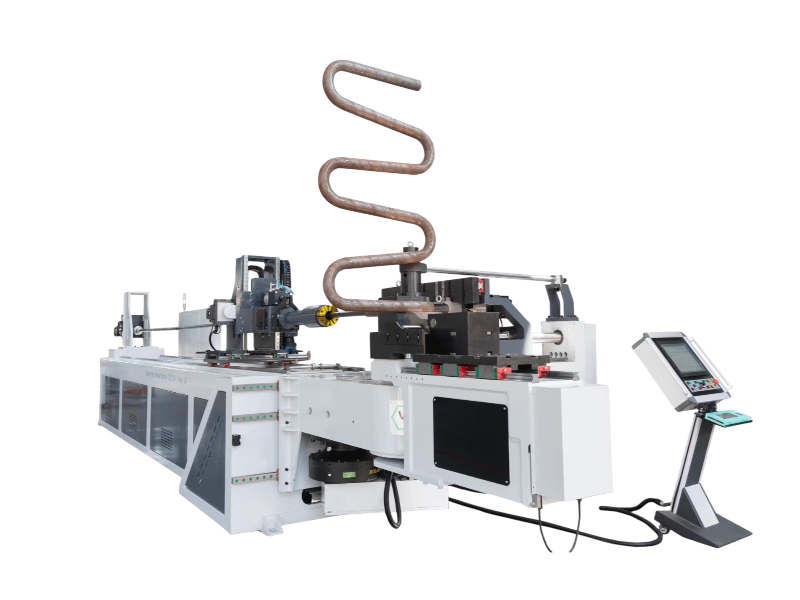

The system includes an integrated 4th Axis Rotary attachment, enabling precise cutting of tubes and cylindrical materials. This advanced capability allows students to learn multi-axis CNC machining concepts such as compound angles, wrap-around geometries, and tube joint preparation. Notably, these are skills directly transferable to aerospace, automotive, and structural fabrication careers.

Designed as a turnkey instructional solution, the QL-EduCut X is delivered fully installed and commissioned. It is also supported with comprehensive instructor training, professional CAD/CAM software, and a minimum three-year parts and labor warranty. Therefore, it is an ideal platform for technical schools, vocational programs, community colleges, and advanced manufacturing training centers. These organizations are seeking safe, industry-aligned laser cutting education.

Technical Specifications

-

Laser Type: Industrial Fiber Laser

-

Cutting Bed Size: 5 ft × 10 ft

-

Mild Steel Cutting Capacity: up to 1/2 in (12.7 mm)

-

Stainless Steel Cutting Capacity: up to 3/8 in (9.525 mm)

-

Aluminum Cutting Capacity: up to 3/8 in (9.525 mm)

-

Achievable Kerf Width: ≤ 0.040 in (≤ 1.0 mm)

-

Rotary Axis: Integrated 4th Axis (Ø25–200 mm tubes, up to 3,000 mm length)

-

CNC Control: Industrial multi-axis controller with touchscreen interface

-

File Formats Supported: DXF, DWG, standard CAD/CAM formats

Safety & Software

-

Fully enclosed Class 1 laser safety design

-

Interlocked protective housing

-

Multiple emergency stop points

-

Instructor-controlled operating modes

-

Password-protected administrative access

-

Integrated CAD software for design

-

Professional CAM software for toolpath generation

-

Nesting software for material optimization

-

Ethernet & USB connectivity

-

Network integration for lab environments

Educational Applications

-

Welding and fabrication training programs

-

Student certification and capstone projects

-

CNC programming and CAM instruction

-

Rapid prototyping and design iteration

-

Tube cutting, joint preparation, and custom fixtures

-

Production of jigs and tooling for training labs

-

Multi-axis machining skill development