Currently Empty: $0,00

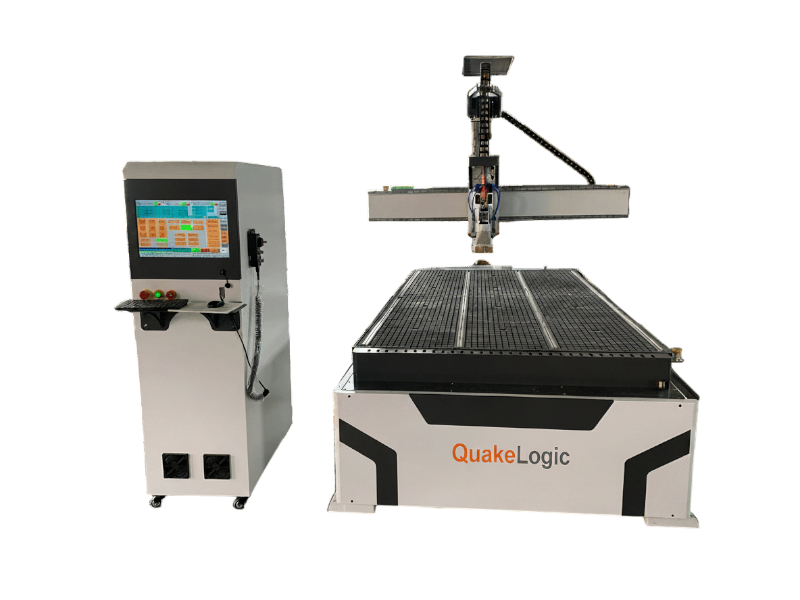

QL Fortis 850 5X – High-Precision 5-Axis CNC Machining Center for Advanced Manufacturing

A high-performance five-axis CNC machining center engineered for precision manufacturing of complex parts. The QL Fortis 850 5X delivers exceptional rigidity, closed-loop accuracy, and reliable multi-axis performance for advanced industrial applications.

OVERVIEW

Description

QL Fortis 850 5X is a high-performance five-axis CNC machining center engineered for manufacturers who demand uncompromising accuracy, rigidity, and long-term operational reliability. Designed for complex, multi-surface machining, it enables complete part processing in a single setup, eliminating repositioning errors while significantly reducing cycle time and production costs.

Built on a rigid U-type machine structure and equipped with a high-torque direct-drive rotary cradle, the Fortis 850 5X delivers exceptional stability even under heavy cutting conditions. A full closed-loop feedback system across all five axes ensures outstanding positional accuracy, repeatability, and long-term precision retention for mission-critical applications.

Featuring a large Ø800 mm precision rotary table, 850 × 800 × 600 mm linear travels, and a 1,000 kg table load capacity, this 5-axis CNC machine is ideally suited for aerospace components, automotive parts, medical devices, mold and die manufacturing, and other high-precision industrial applications.

The machine is powered by a high-performance electric spindle with HSK-A100 interface, precision roller linear guideways, and a fast 32-tool automatic arm-type tool changer, providing the flexibility required for both heavy roughing and ultra-fine finishing operations. Integrated RTCP (Rotational Tool Center Point) functionality and advanced CNC control technology ensure precise multi-axis coordination during simultaneous five-axis machining.

The QL Fortis 850 5X reflects QuakeLogic’s commitment to production-ready CNC solutions, delivering the accuracy, durability, and performance required by today’s most demanding manufacturing environments.

Key Features

-

Five-axis simultaneous CNC machining capability

-

Rigid U-type machine structure for high stability

-

Direct-drive A/C rotary cradle with circular grating feedback

-

Full closed-loop positioning on all axes

-

RTCP (Rotational Tool Center Point) functionality

-

High-torque electric spindle with HSK-A100 interface

-

Single-setup complete part machining

-

Designed for continuous industrial operation

Technical Highlights

-

Table Diameter: Ø800 mm (H7 precision)

-

Linear Travel (X/Y/Z): 850 / 800 / 600 mm

-

A-Axis Tilt Range: -60° to +120°

-

C-Axis Rotation: Continuous 360°

-

Table Load Capacity: 1000 kg

-

Spindle Speed Range: 1 – 12,000 rpm

-

Spindle Power: 54 kW

-

Tool Magazine: 32-position automatic ATC

-

Positioning Accuracy (X/Y/Z): 0.006 mm

-

RTCP Accuracy: 0.04 mm

Applications

-

Aerospace structural components

-

Automotive precision parts

-

Medical device manufacturing

-

Mold & die machining

-

Complex 3D and multi-surface components

-

Advanced industrial fabrication