Currently Empty: $0,00

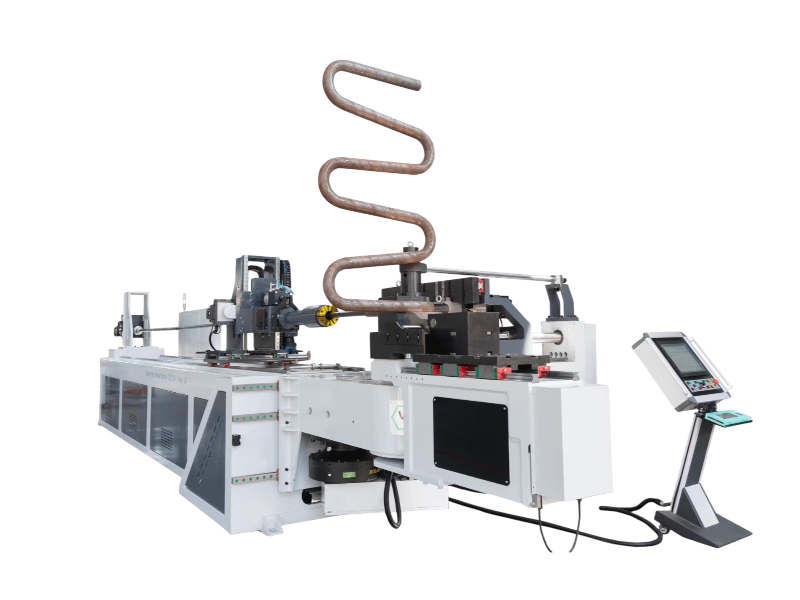

QuakeLogic QL-TubeMaster Pro X CNC Electric Mandrel Bender

High-precision fully electric CNC mandrel tube bender with FANUC controls, ±0.003″ accuracy, variable radius bending, and complete tooling. Engineered for aerospace, defense, and mission-critical manufacturing applications.

OVERVIEW

Description

The QuakeLogic QL-TubeMaster Pro X CNC Electric Mandrel Bender is a high-precision, fully electric CNC tube bending system. It is engineered for aerospace, defense, and high-reliability industrial manufacturing environments. Designed to eliminate the limitations of hydraulic systems, it delivers exceptional accuracy, repeatability, and long-term operational stability.

Powered by an advanced fully electric, servo-driven architecture and FANUC industrial CNC controllers, the QL-TubeMaster Pro X achieves bending accuracy of ±0.003 inches. This ensures compliance with the strict dimensional tolerances required for aircraft hydraulic lines and fuel systems. It also meets the demands for mission-critical structural tubing. The system supports clockwise and counterclockwise bending, variable radius control, and multi-plane bend programs. It operates with consistent, vibration-free motion.

This turnkey solution is supplied with a complete tooling package. The package includes bend dies, clamp dies, pressure dies, mandrel assemblies, wiper dies, and an automatic mandrel lubrication system. Integrated safety systems, such as Keyence area scanners, light curtains, safety interlocks, and emergency stops ensure full compliance with North American workplace safety standards.

Configured specifically for North American facilities, the QL-TubeMaster Pro X operates on 208V / 3-Phase / 60Hz power. It complies with CSA C22.1:21 electrical standards and includes installation, commissioning, and on-site operator training. It is backed by QuakeLogic’s comprehensive warranty and lifecycle support. Consequently, the system is built for continuous, high-precision production with minimal downtime.

Key Features & Capabilities

-

Fully electric CNC architecture (no hydraulics)

-

FANUC industrial servo drive controllers

-

±0.003″ bending accuracy

-

Clockwise & counterclockwise bending

-

Variable radius and multi-plane bending

-

180° maximum bend angle

-

Supports aluminum, titanium, and stainless steel

-

Vibration-free, servo-controlled motion

-

1,000+ programmable bend sequences

Technical Specifications

-

Bending Accuracy: ±0.003 in

-

Maximum Bend Angle: 180°

-

Minimum Tube OD: 1.00 in

-

Minimum Wall Thickness: 0.083 in

-

Control System: FANUC CNC controllers

-

Power Requirement: 208V / 3-Phase / 60Hz, max 30A

-

Compliance: CSA C22.1:21, UL-listed components

-

Programming Capacity: 1,000+ programs

-

Operation: Fully electric, servo-driven

Tooling, Safety & Support

Included Tooling

-

Complete bend, clamp, and pressure die set

-

Mandrel assembly with balls and links

-

Wiper die and collet system

-

Automatic mandrel lubrication system

-

Tool change fixtures and storage

Safety Systems

-

Keyence area scanner perimeter protection

-

Light curtains and safety gates

-

Emergency stop and safety interlocks

-

Lockout/Tagout (LOTO) compatible design

Support & Warranty

-

Minimum 24-month comprehensive warranty

-

Installation, commissioning, and training included

-

Remote diagnostics and technical support

-

Long-term spare parts availability