Currently Empty: $0,00

Tube Metal Cutter

The OMNI6000T cnc laser tube cutter for metal, also known as a laser tube cutting machine, is used to cut round, square, and other metal tubes.

Carbon steel, stainless steel, aluminum alloy, galvanized sheet, titanium alloy, manganese alloy, and other materials may be cut with a laser pipe cutting machine.

It is extensively utilized in metal tube processing, machinery manufacturing, car parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum equipment, food machinery, ornamental ads, and many other applications.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

FEATURES OF HIGH PRECISION CNC TUBE LASER CUTTER

The pipe processing range: 6000mm*10220mm

Power: 1,500 – 6,000 watts range (1.5kW-4kW)

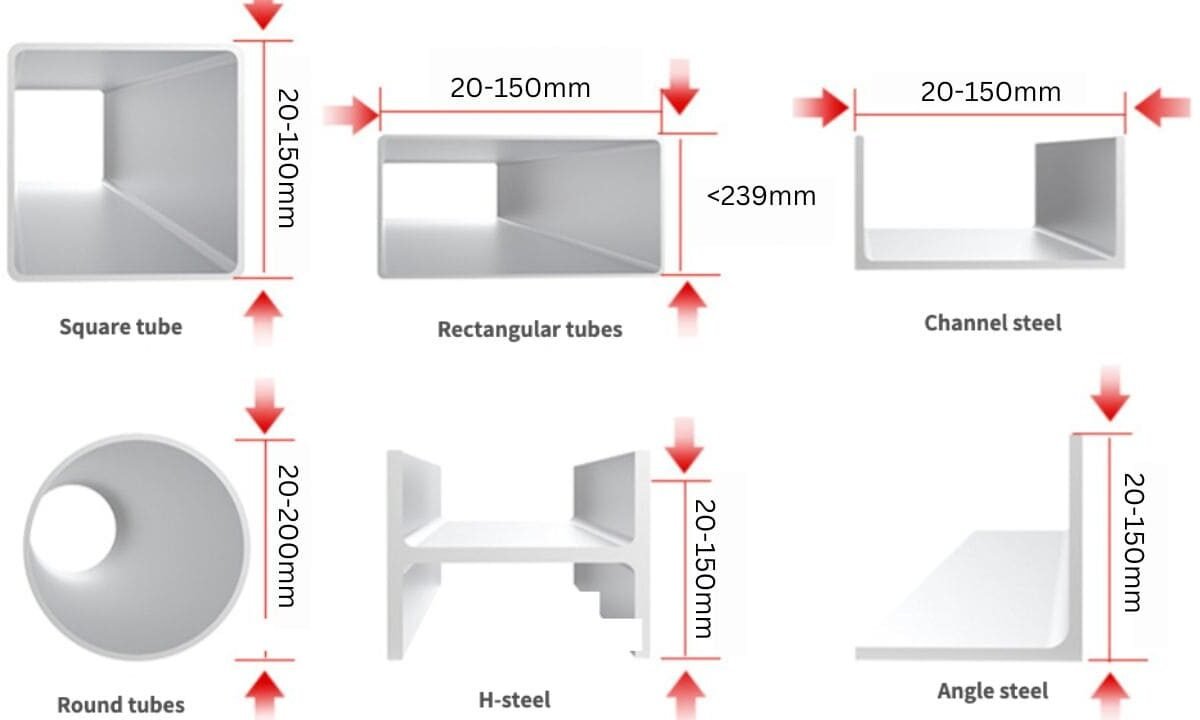

Round Tube Diameter:Φ20mm-200mm (Φ0.8″-7.8″)

Square Tube Length: 20*20mm-150*150mm(0.8″*0.8″-5.9″*5.9″)

Passed CE/FDA certifications

2 Year Warranty

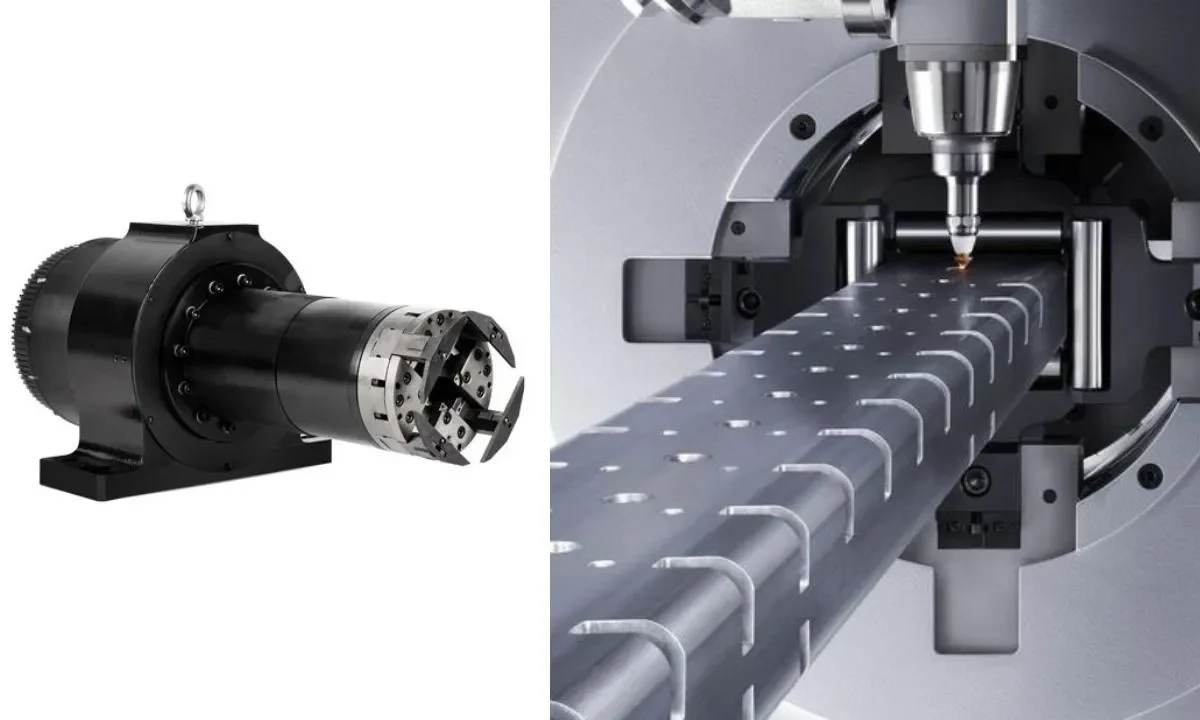

PNEUMATIC SELF-CENTERING CHUCK

Precision Trifecta: Conquer Tubes with Speed, Efficiency, Grip

Low Inertia: Blast through small-tube jobs with rapid starts and stops, maximizing output.

Ultra-Short Swarf: Embrace sustainability and minimize waste with deep chuck integration.

Unwavering Clamping: Powerful grip tackles any tube shape, ensuring consistent, high-quality cuts.

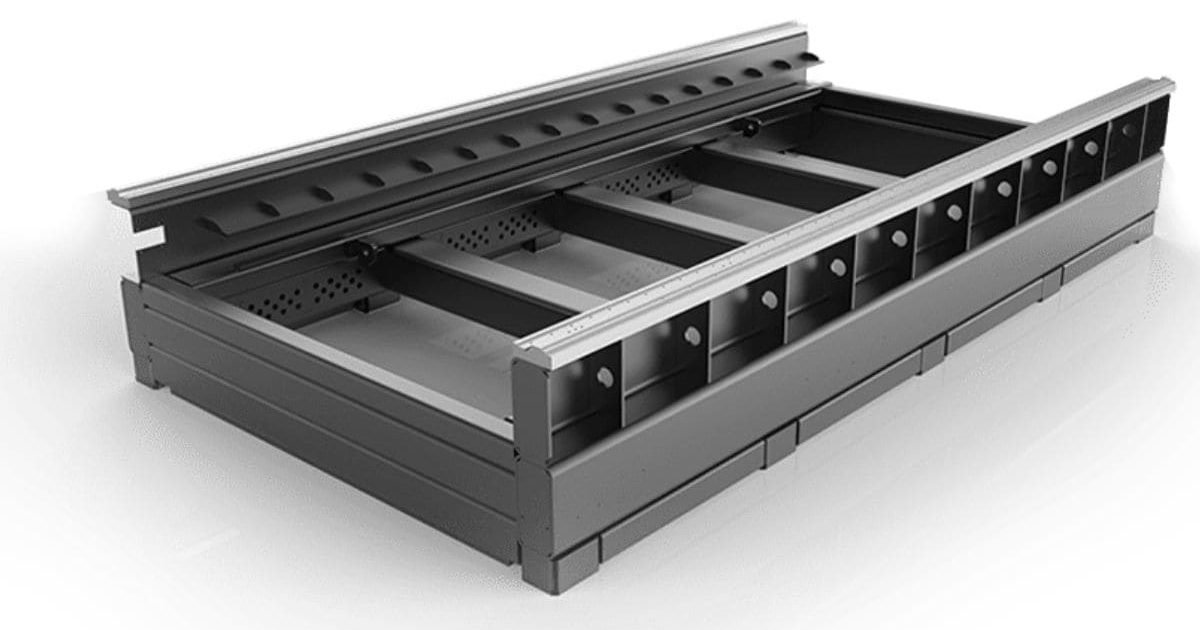

EXTRA SOLID FRAME

Extra heavy duty welded steel frame and gantry for maximum straightness and rigidity

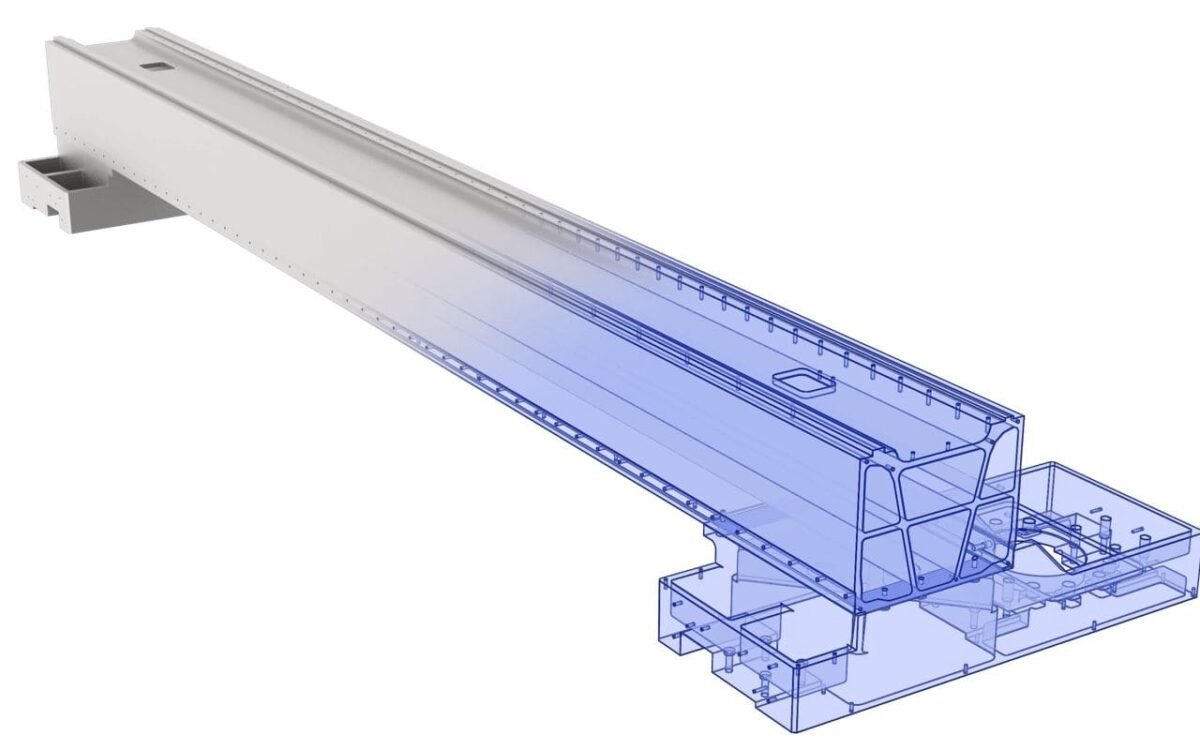

COLD DRAWN EXTRUDED ALUMINUM BEAM

Cast aluminum beam with high rigidity,And the weight is 1/2 lingter than traditional welding iron gantry.

AUTOMATIC TUBE SLIDE & INTEGRATED SUPPORT

Effortless Tube Handling, Maximized Efficiency

Automatic Tube Slide: Tubes glide effortlessly out of the machine, eliminating manual lifting and forklifts.

Integrated Support Platform: Receives cut tubes for seamless post-processing, keeping your workflow fluid.

Boost productivity by up to 20% with faster unloading and smoother transitions.

Minimize risk of injuries and create a safer workspace.

Save valuable floor space by eliminating forklift traffic.

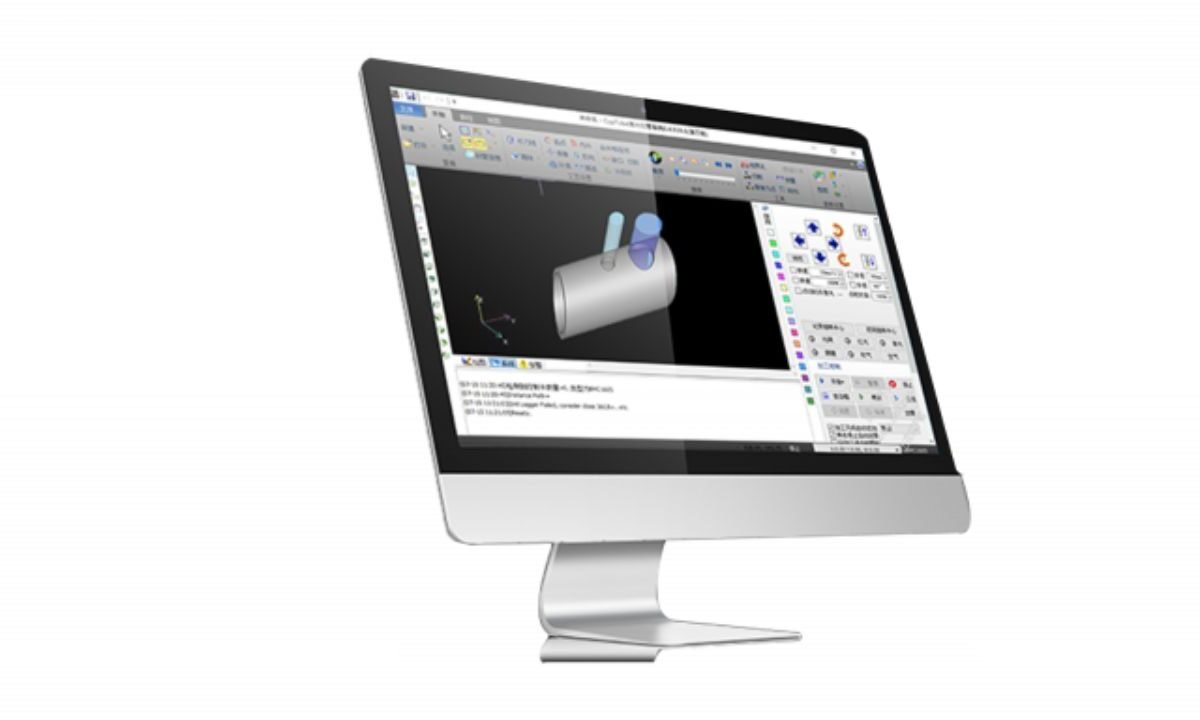

TUBEPRO TUBE CUTTING SOFTWARE

It is equipped with an FSCUT3000S pipe cutting system, which enables high-precision and high-efficiency cutting of square pipes, round pipes, racetrack-shaped and oval-shaped stretched pipes, angle steel, and channel steel.

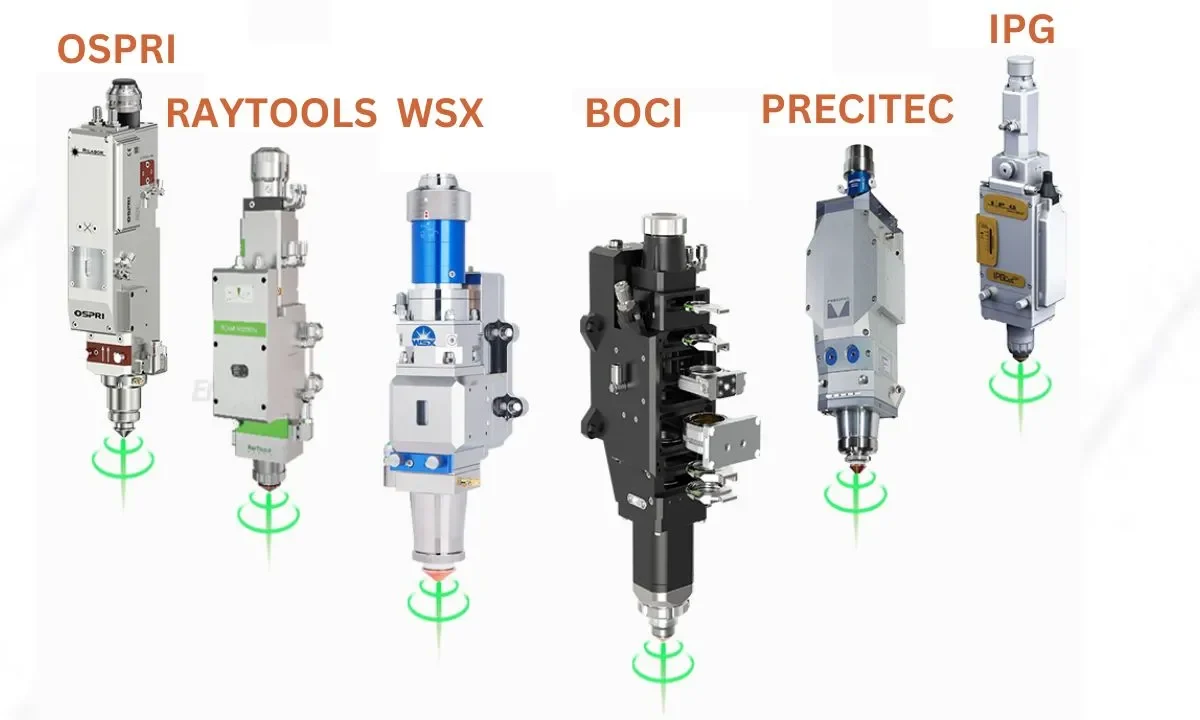

GLOBAL PRECISION, BUILT IN

Crafted with laser heads from industry leaders, this machine delivers unrivaled cutting power and reliability. Experience the difference, cut by cut.

VARIOUS TUBE CUTTING

CNC laser tube cutter can easily cut H steel, I-beam, angle steel, channel steel, and other profiles, as well as drop-shaped and concave-shaped tubes, with a 3D laser cutting head.

Parameters

| Specification | Details |

|---|---|

| Machine Model | OMNI 6000T |

| Tube Cutting Dimension (mm) | 6000mm × φ10~220mm (Square tube: 10×10~150×150mm) |

| Laser Head | Fiber laser (1KW, 2KW, 3KW, 4KW, 6KW) |

| Maximum Rotational Speed | 100 r/min |

| Maximum Load Weight | 150 KG |

| Max Cutting Speed | 80 m/min (262′/min) |

| Max Moving Speed | 60 m/min (196′/min) |

| Max. Acceleration Speed | 0.8 G |

| Repeatability | ±0.02 mm |

| Min Cutting Line Width | 0.02 mm |

| Motor | Servo motor and driver |

| Voltage | AC380V/50Hz, 3PH; 220V/60Hz, 3PH; AC440V/50Hz, 3PH |

| Operating System | RUIDA |

| File Format | plt, dxf, ai |

| Power | Carbon Steel (mm) | Stainless Steel (mm) | Aluminum (mm) | Brass (mm) |

|---|---|---|---|---|

| 1KW | 0.4–12 | 0.4–5 | 0.4–3 | 0.4–3 |

| 1.5KW | 0.4–16 | 0.4–6 | 0.4–5 | 0.4–5 |

| 2KW | 0.4–18 | 0.4–8 | 0.4–6 | 0.4–6 |

| 3KW | 0.4–20 | 0.4–12 | 0.4–8 | 0.4–6 |

| 4KW | 0.4–25 | 0.4–12 | 0.4–12 | 0.4–8 |

| 6KW | 0.4–25 | 0.4–20 | 0.4–16 | 0.4–14 |