Currently Empty: $0,00

Sheet & Tube Metal Cutter

Compact and versatile system

Cater to diverse processing requirements

Offering a range of tube & sheet metal cutting capabilities within a single machine

Cost-effective & Efficient

Unparalleled Dependability & Safety

Space-saving & Adaptable Configuration

High Return on Investment

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

CAPABILITIES OF THE TUBE AND SHEET LASER CUTTING MACHINE

Our CNC laser cutter cuts through nearly any type of metal quickly easily with a high range of precision and accuracy.

OMNI enables more steel fabricators to add high-precision cutting capability to their operations.

This can achieve superior cut quality and tolerance for fine featured cutting on materials from gauge to plate thickness.

Pipe cutting system meets the demand of round tube, square tube and rectangular tube cutting.

INNOVATIVE COLLISON PREVENTION TECHNOLOGY

Dependable production while minimizing potential damage to the laser head.

Say farewell to the cumbersome and time-consuming manual focusing required to process sheets of varying materials and thicknesses.

Auto focus laser head system reduces focusing time by 50% by automatically adjusting to the optimal position, thus enhancing productivity even when piercing thick plates.

Furthermore, the lens focus can be adjusted automatically, allowing for the automatic perforation and cutting of plates with varying thicknesses.

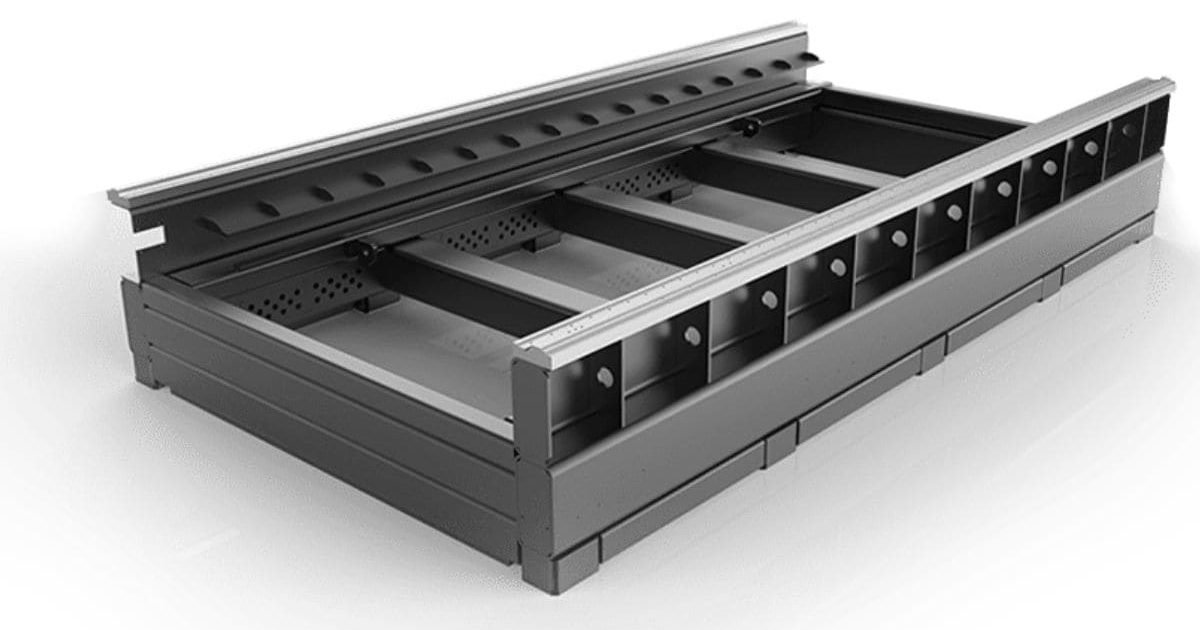

EXTRA SOLID FRAME

Rigidity: Providing a solid foundation for the cutting process.

Stability: Ensuring a stable and accurate cutting experience.

Durability: Built to withstand prolonged use and exposure to harsh environments.

Precision: Allowing for consistent and accurate cutting results.

Accessibility: Making maintenance and servicing simple and straightforward.

Customizability: Customized to meet the specific needs of the user, such as the size of the cutting bed or the addition of specialized features.

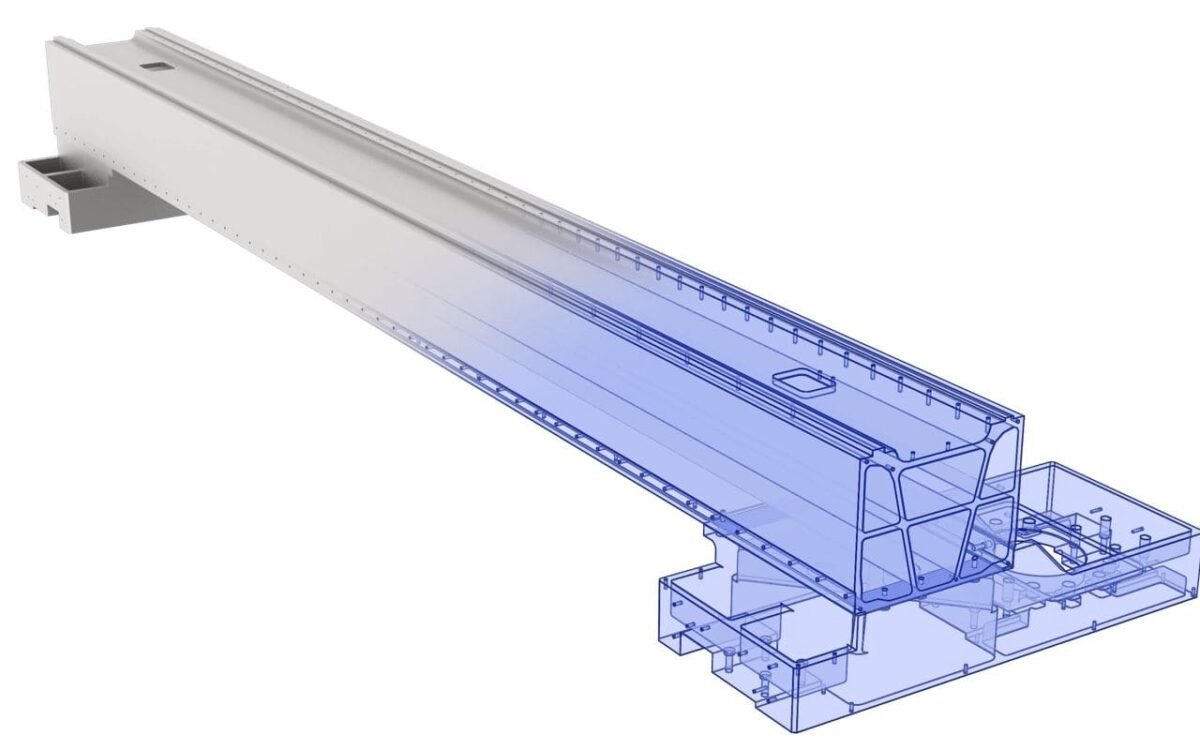

COLD DRAWN EXTRUDED ALUMINUM BEAM

High Strength: Ensuring a stable cutting process.

Lightweight: Reducing the overall weight of the machine, making it easier to move and transport.

Rigidity: Helps to minimize vibrations during the cutting process, resulting in precise and accurate cuts.

Thermal Stability: Allowing for consistent performance even in high-temperature environments.

Low Maintenance: Reducing downtime and maintenance costs.

Longevity: Providing long-lasting performance and ensuring a high return on investment.

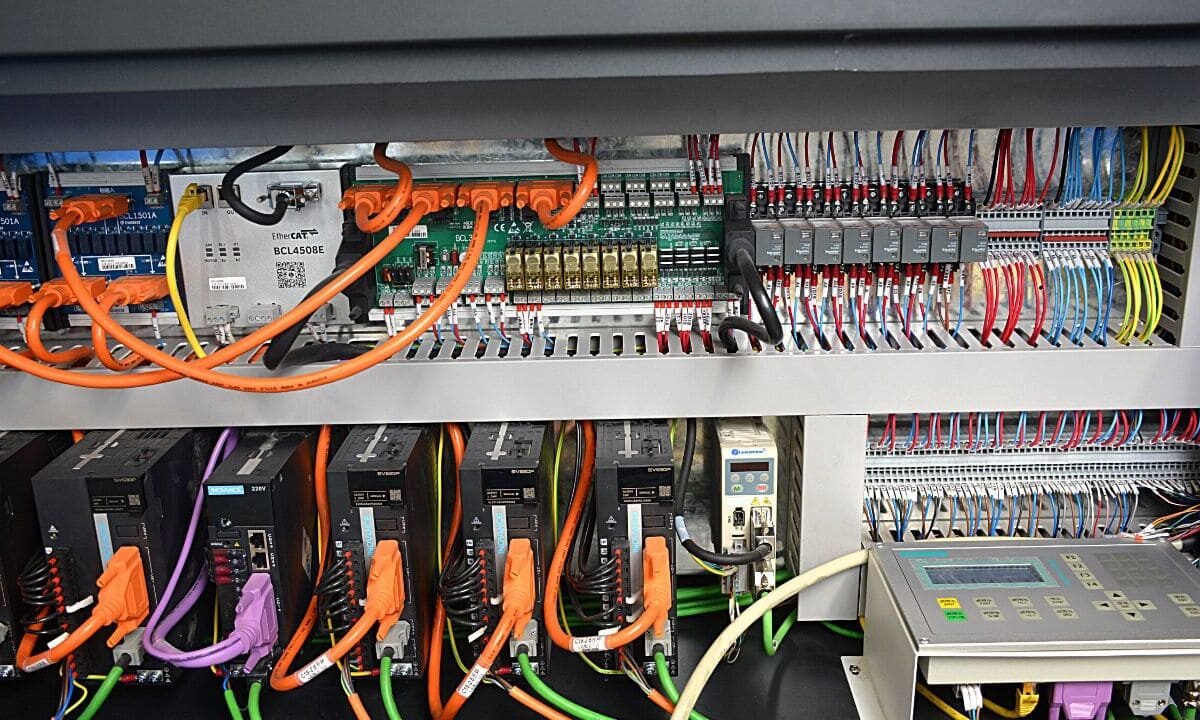

WORLD FAMOUR DRIVING SYSTEM

High Precision: Ensuring accurate and consistent cutting results.

Smooth Operation: Minimizing vibration and ensuring optimal cutting performance.

Enhanced Speed: Increasing the cutting efficiency and throughput of the machine.

Energy Efficiency: Reducing the overall energy consumption of the machine and lowering operating costs.

Low Maintenance: Highly reliable and requires minimal maintenance, reducing downtime and maintenance costs.

User-Friendly: Allowing operators to quickly and easily adjust settings and parameters for optimal performance.

TUBELAR CUTTING FUNCTION

This machine allows Auto Find Tube Center in Production.

TubePro can locate and offset tube deviation from chuck rotation center in production to guarantee a high cutting precision.

Rotational and tilt cutting: For cutting tubes, the cutting head or the tube would need to rotate and tilt to cut around the circumference of the tube. The machine’s motion system would have rotation and multi-axis tilting capability to cut at any angle around tubes.

QUALITY CYPCUT & TUBE PRO LASER CUTTING SOFTWARE COMBINED INTUITIVE TOUCH SCREEN INTERFACE

Simplifies the laser cutting process, ultimately leading to an improved user experience.

User-friendly interface is complemented by robust compatibility and processing capabilities, ensuring seamless operations.

Integration of CAD, Nesting, and CAM modules into a single platform provides a comprehensive solution that enables users to initiate the metal processing workflow with just a few clicks.

This all-encompassing solution streamlines the entire process from drawing and nesting to workpiece cutting, further enhancing the efficiency of the overall operation.

Videos

Parameters

| Specification | Details |

|---|---|

| Working Dimension (mm) | 1500 × 3000 |

| Laser Head | Fiber laser 1000W–6000W |

| Max Cutting Speed | 660 mm/s |

| Repeatability | ±0.03 mm |

| Max. Rapid Travel Speed | 20 m/min |

| Max Acceleration | 1.5 g |

| Total Power | Less than 6 KW |

| Drive System (X and Y axis) | Rack and Pinion, Rail Linear Bearing |

| Motor | Yaskawa Servo Motor & Drive (Other Brand Optional) |

| Work Table Max Load | 700 KG |

| Operating System | FSCUT3000 |

| File Format | plt, dxf, ai |

| Metal Safety Cover | No |

| Shuffle Table | No |

| Machine Size | 3900 × 2760 × 1650 mm |

| Voltage | AC380V/50Hz, 3PH; 220V/60Hz, 3PH; AC440V/50Hz, 3PH |

| Power Protection Level | IP54 |