Currently Empty: $0,00

5×10 Router Table

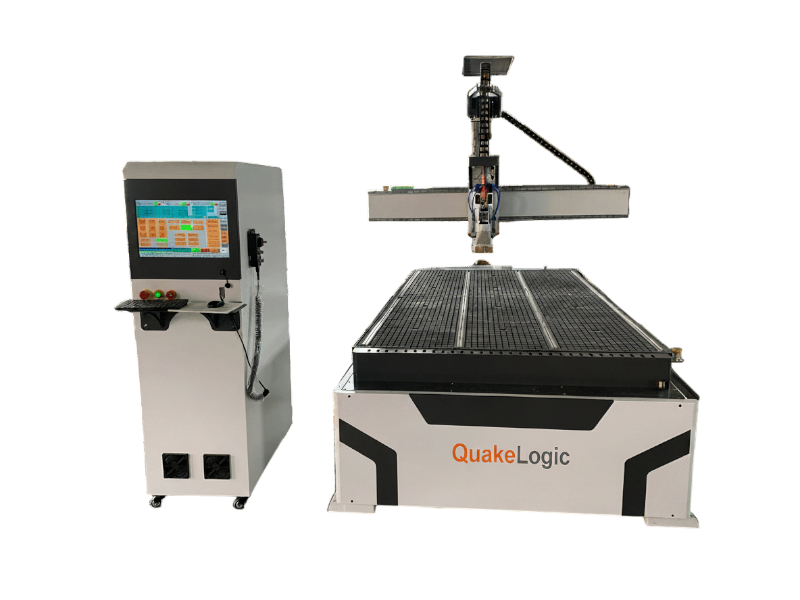

The E series 5×10 CNC Router from OMNI CNC is a powerful and versatile machine that can handle a wide range of CNC routing tasks.

With a cutting area of 5 feet by 10 feet, this machine is perfect for cutting and engraving a variety of materials, including wood, plastics, composites, and more.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

Thicken Welded Machine Solid Steel Frame

High-frequency Tool Calibration

4hp/6hp/11hp Spindle

DSP Remote Control User-friendly OperatorInterface

Extremely Fast Precision Dual Y-axis Micro-stepping or Servo Drives in a 3-Axis Motion Controller

MACHINE CONFIGURATION

THICKEN WELDED GANTRY & FRAME

CNC router features a strong and sturdy steel tube bed structure, providing amazing stability while cutting.

With dual support, direct drive, and a helical rack and pinion gantry system, it can move at speeds of up to 40m/min and cut at up to 15 m/min.

The device weighs approximately 1500KG and has a Z-travel range of 200mm to 300mm.

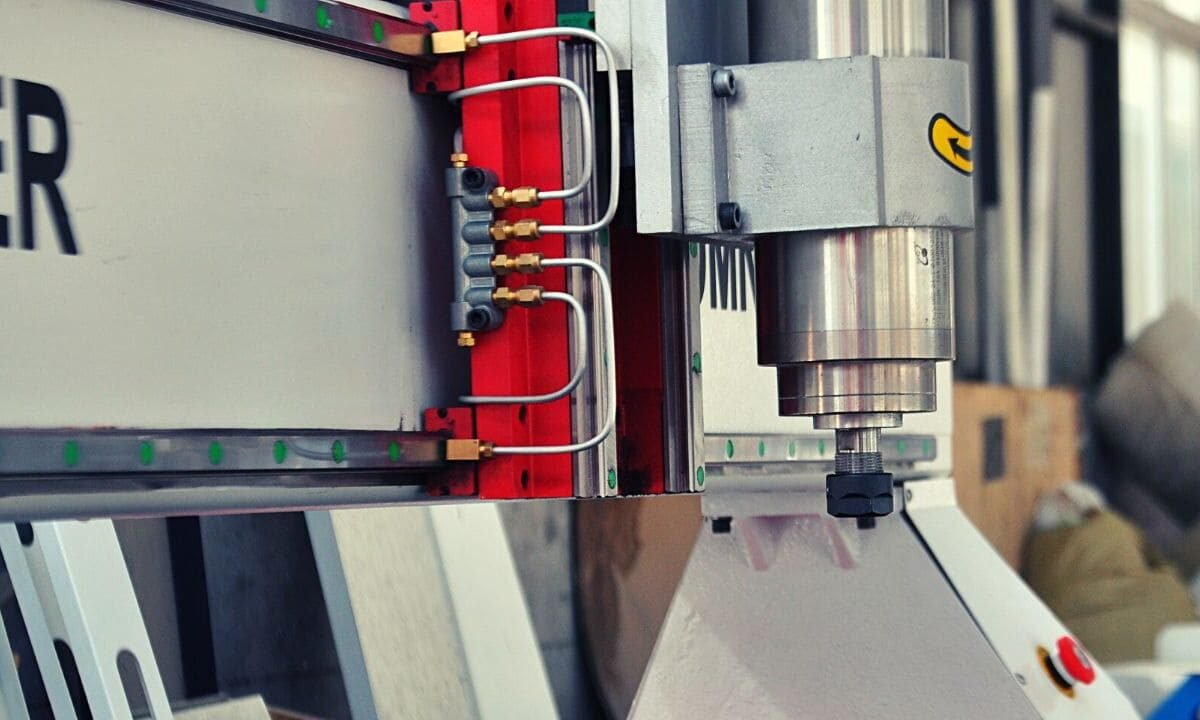

WATERCOOLING & AIRCOOLING SPINDLES FOR OPTION

Italy HSD/Hiteco spindle and quality water cooling down spindle made in China. Select spindle according to your budget. HSD and Hiteco spindle are incredibly trustworthy as well as has service divisions around the globe in case your CNC spindle needs servicing.

SOLID 5‘ *10’ WORKING TABLE

Excellent quality table with vacuum function (optional).

In addition to its cutting capabilities, the 5×10 CNC Router is also designed for efficiency and ease of use.

It features a dust collection system that keeps the work environment clean, as well as a user-friendly tool sensor that automatically detects and measures the length and diameter of cutting tools and router bits.

QUALITY HANDHELD CONTROLLER

A DSP handheld controller is a type of control system for CNC machines that features a handheld device with USB interface for easy and convenient control.

It is known for its user-friendly interface and mobility, making it a popular choice for entry level CNC machines

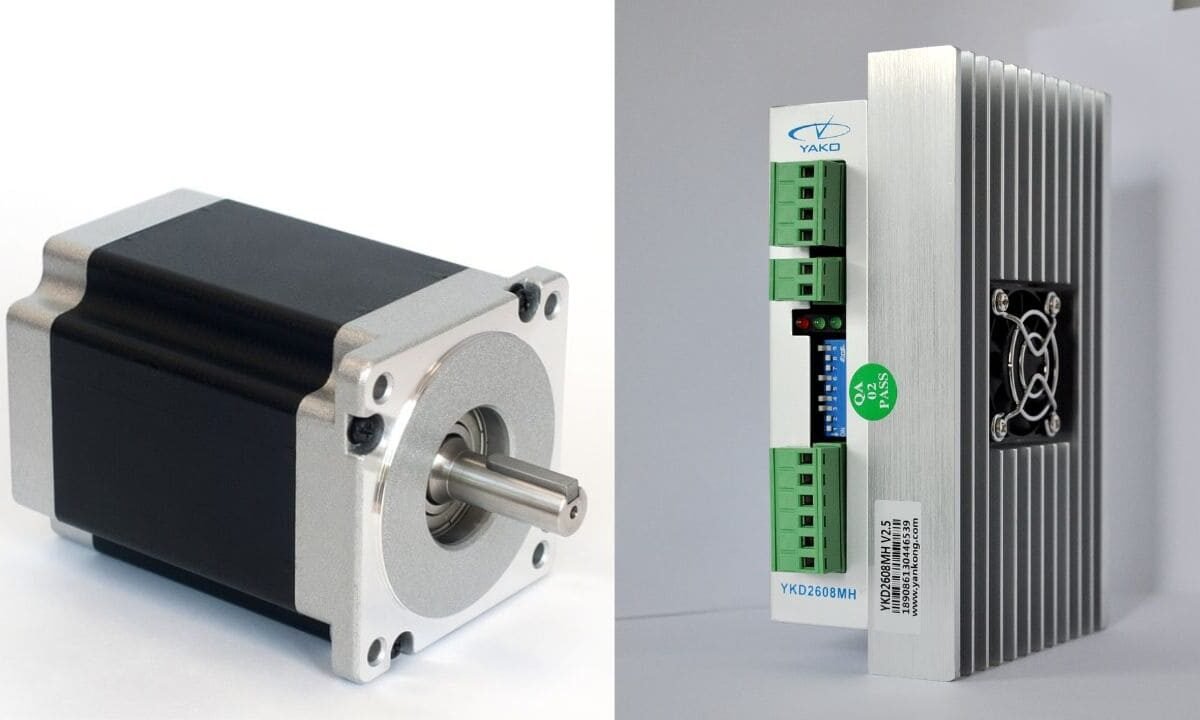

MOTOR & DRIVER

Quality dual drive for the Y-axis gantry that effectively avoids racking of the gantry due to unsynchronized motion that is seen in solitary drive systems.

LINEAR MOTION

The helical rack and pinion drive system on both the X as well as Y axes, linear guide on 3 axis, and also ballscrew on z. These offer exceptionally smooth motion as well as tight control, causing very precise, top notch cuts.

Helical gears provide faster acceleration as well as better toughness than straight cut gears, making them excellent for commercial CNC work.

COMPATIBLE

Our OMNI control systems are compatible with popular CNC software such as Aspire, Vcarve, and Fusion360.

Once an order is placed, we will send you a download link for the post-processor that is compatible with your software.

Parameters

| Model No. | OMNI1530E, OMNI1325E, OMNI2030E |

| X,Y-Axis Travel | 1300*2500 ,1500*3000, 2000*3000mm |

| Z-Axis Travel | 200mm or others |

| Spindle Power | 3kw watercooling 24000rpm or higher power; HSD3kw aircooling 18000rpm or higher power |

| Repeatability | +/- 0.05mm |

| Drive System X and Y axis | Rack and Pinion, rail linear bearing |

| Max. Rapid Travel Speed | 15m/min-40m/min |

| Drive System Z axis | Lead Screw, rail linear bearing |

| Standard Work Surface | aluminium T-Plate Extrusion Combined Bakelite Vacuum Table |

| Motor | Stepper/Servo |

| Spindle Protection Device | digital spindle temperature monitor (not fitted for air-cooling spindle) |

| Working Voltage | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ, 3PH |

| Command Language | G Code&M Code |

| Collet | ER20 or ER25 or ER32 |

| Operating System | DSP Handheld Controller/ NC studio/ Syntec |