Currently Empty: $0,00

48 Gantry Moving

OMNI high-performance 5 axis CNC gantry router for sale is well-suited for complex machining applications across diverse industries. As a heavy-duty continuous-use machine, it can reliably process a wide range of materials from lightweight wood and foam to stronger composites, ferrous and non-ferrous metals.

OVERVIEW

Description

QuakeLogic is an authorized distributor of OMNICNC

Due to the flexibility of the OMNI 5 axis cnc gantry router for sale, it is commonly used for mold making, machining moulds in wood, resin tooling board, EPS and composites, trimming of vacuum formed mouldings, plastic fabrication, GRP machining, props and model making, profiling, solid surface machining and contouring, various large metalloid mould.

It is especially designed for industry of automotive, marine, defense, medical, oil & energy, musical instrument etc. It is suitable for 3d surface engraving and shape cutting of large-scale instruments.

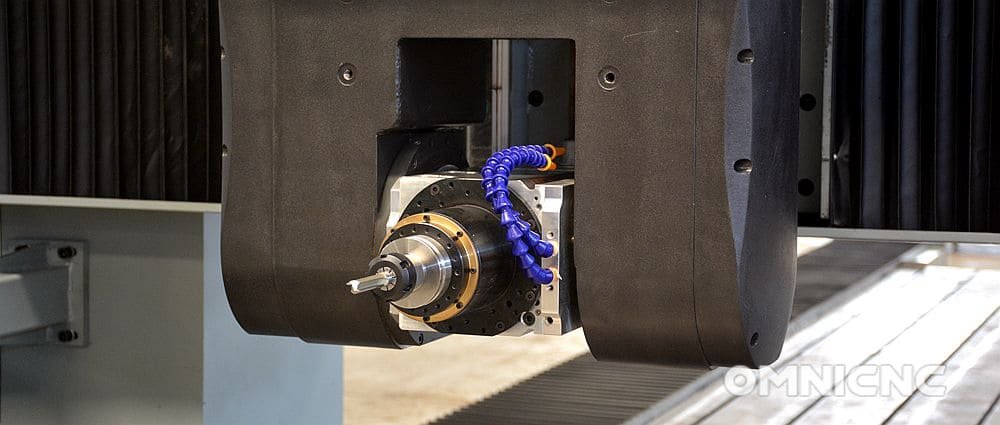

HITECO 30KW SPINDLE

Designed for machining wood and composite materials

Wide range of electrospindle powers available

Compressed air cooled electrospindle version available

EXTRA SOLID GANTRY & FRAME

Extra heavy duty welded steel frame and gantry for maximum straightness and rigidity

5-Axis Moving Gantry

5 axis cnc router controller – 5 Axis CNC Router Gantry Moving

WORLD FAMOUR CONTROL SYSTEM

SYNTEC /SIEMENS – PC interfaced Numerical Control System

WORLD FAMOUR DRIVING SYSTEM

Yaskawa servo drivers and motors for high power and speed

Stainless Steel High Speed Cutting

AUTO TOOL CHANGER

8 – 16 position rotary ATC with HSK precision tool clamping, saving tool changing time to ensure high efficiency manufacturing.

Parameters

| X,Y-Axis Travel | 1220*2440*950mm |

| Spindle Power | 10kw HSD/30KW Hiteco spindle, 1000-24000rpm, liquid cool |

| C travelling | ±213° |

| A travelling | ±135° |

| Beam spacing(MM) | 4260 |

| Beam Height(MM) | 2150 |

| Tool magazine | Carrousel tool tool magazine (8positions) |

| Frame | Cast steel |

| Repeatability | +/- 0.05mm |

| Max. Rapid Travel Speed | 25m/min |

| Total Power | 24KW |

| Maximum lifting weights | 7.5T |

| Drive System X and Y axis | Rack and Pinion, rail linear bearing |

| Drive System Z axis | Lead Screw, rail linear bearing |

| Moving Type | Table moving |

| Motor | Yaskawa Servo motor and driver |

| Working Voltage | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ, 3PH |

| Operating System | Osai / Siemens / Syntec |

| Command Language | G Code&M Code |

| Tool Holder | HSK63F |

| Collet | BT40 |

| Software (Optional) | MasterCAM, Powermill, AlphaCAM i.e. |