Total: $3.308,00

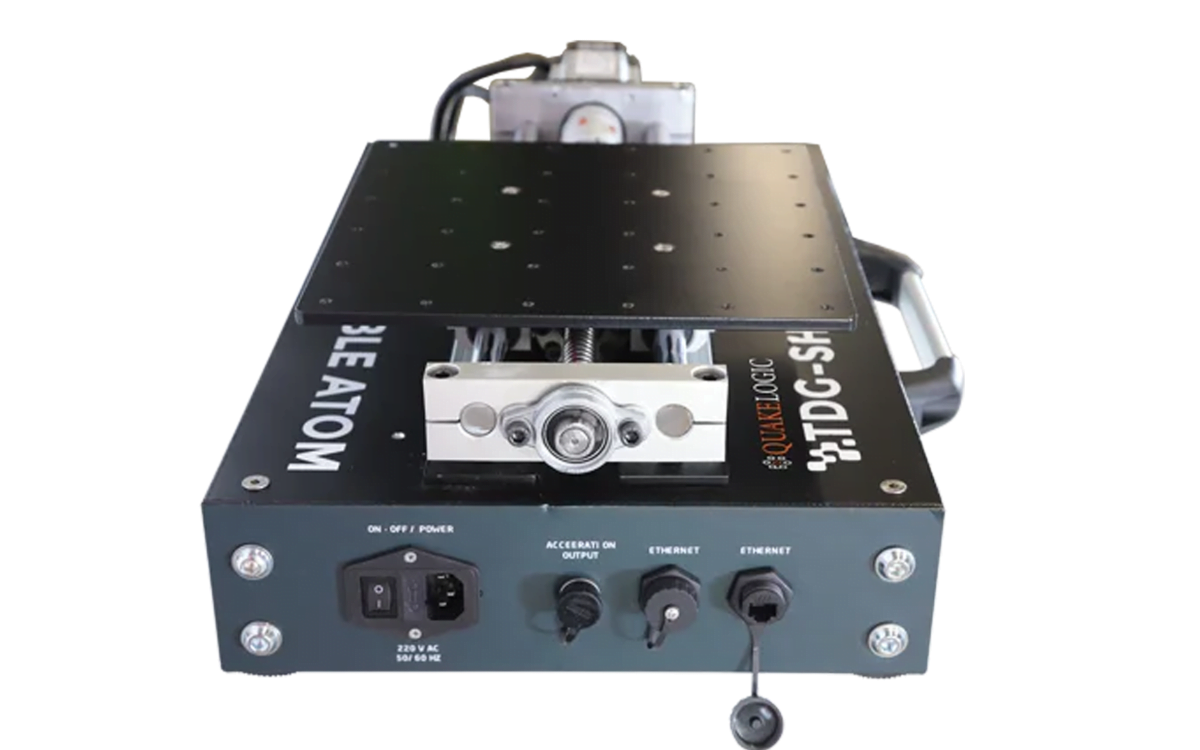

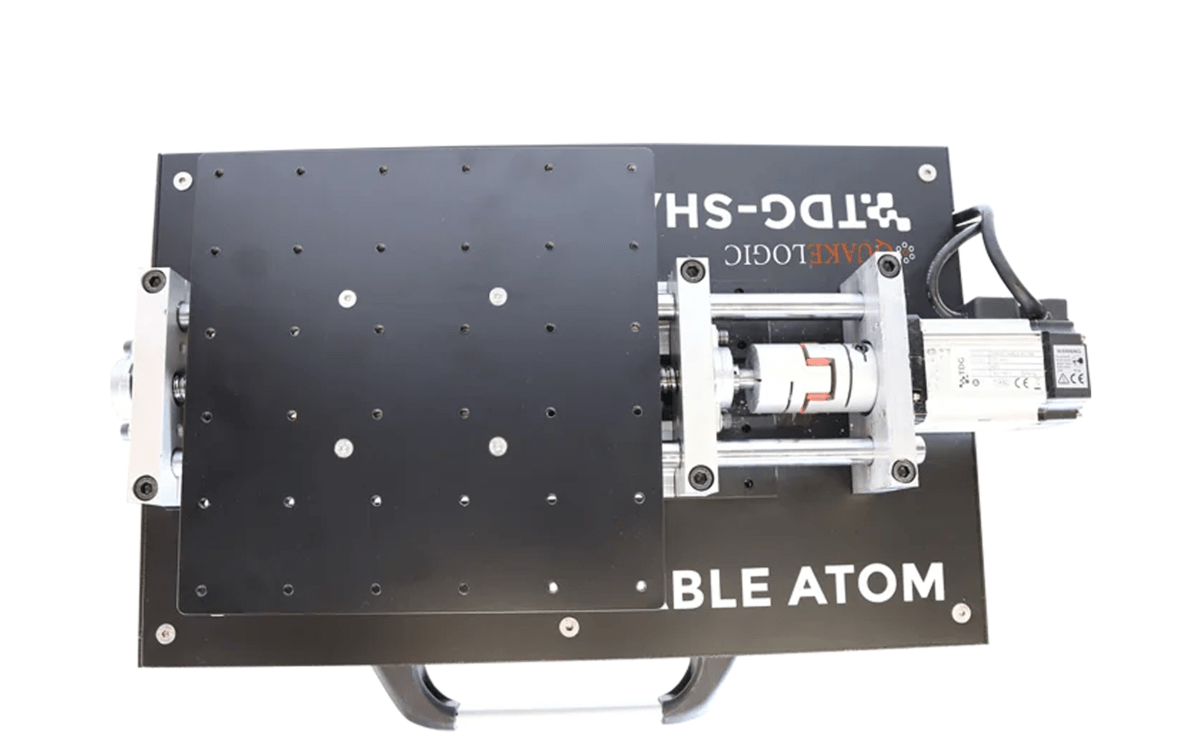

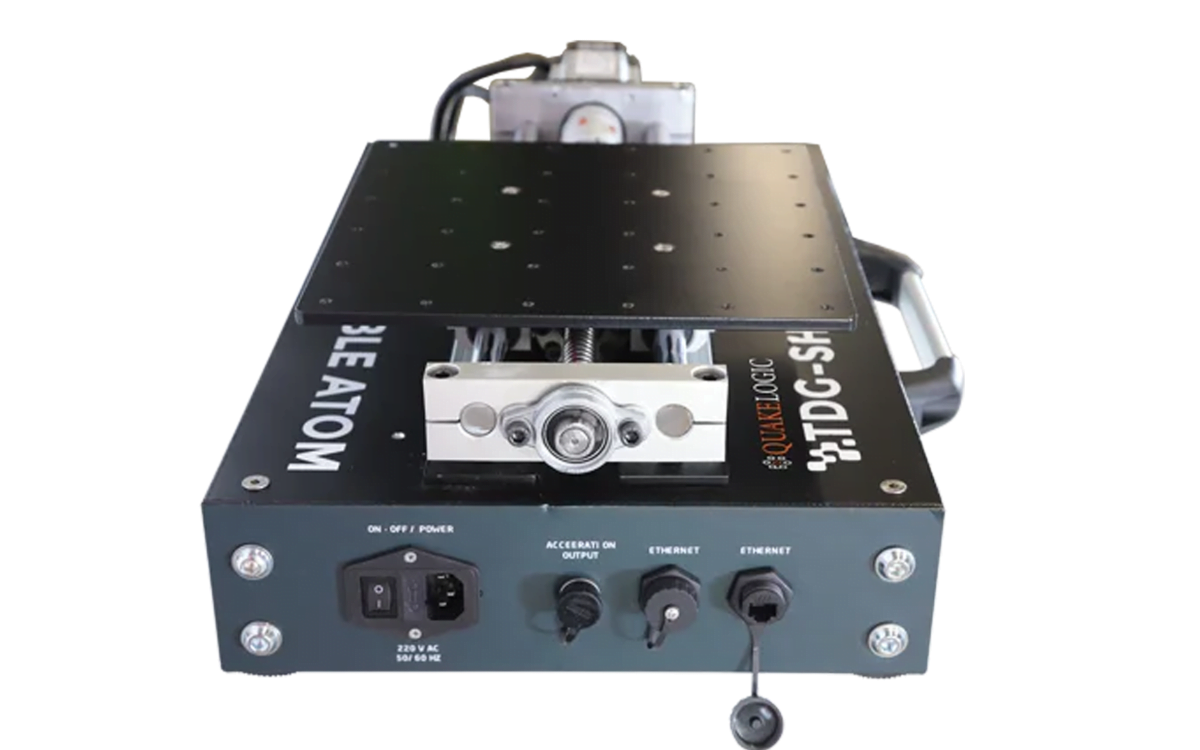

ATOM is a portable, high-precision and budget-friendly uni-axial SHAKETABLE. We have now two different models of the ATOM shake table as ATOM-25 and ATOM-40. ATOM-25 has a 250 mm x 250 mm moving table and ATOM-40 has a 400 mm x 400 mm moving table.

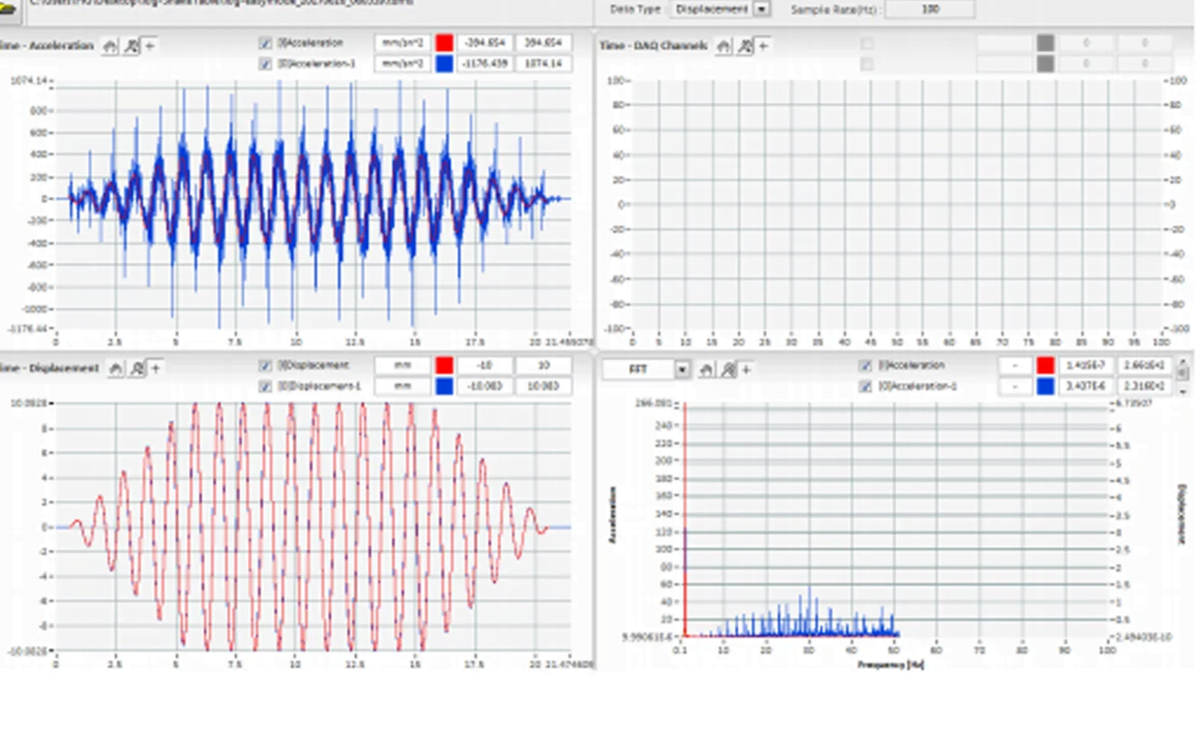

ATOM is an excellent instrument for simulating earthquakes using actual records, or waveforms such as sine, triangle, boxcar, etc. The user can also defined acceleration, velocity or displacement input signal easily.

It is ideal for calibrating accelerometers, seismometers and other seismic instruments. ATOM is also used for simulating earthquakes using actual records, waveforms such as sine, triangle, etc. or user defined acceleration or displacement input signal.

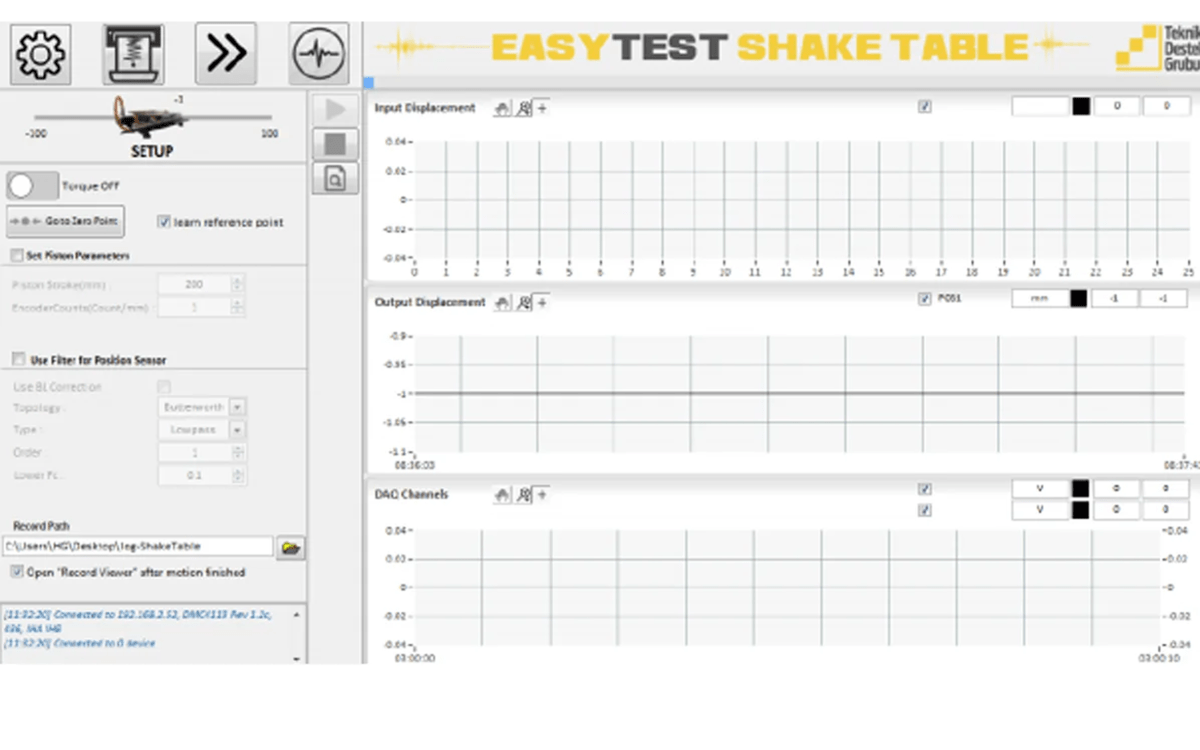

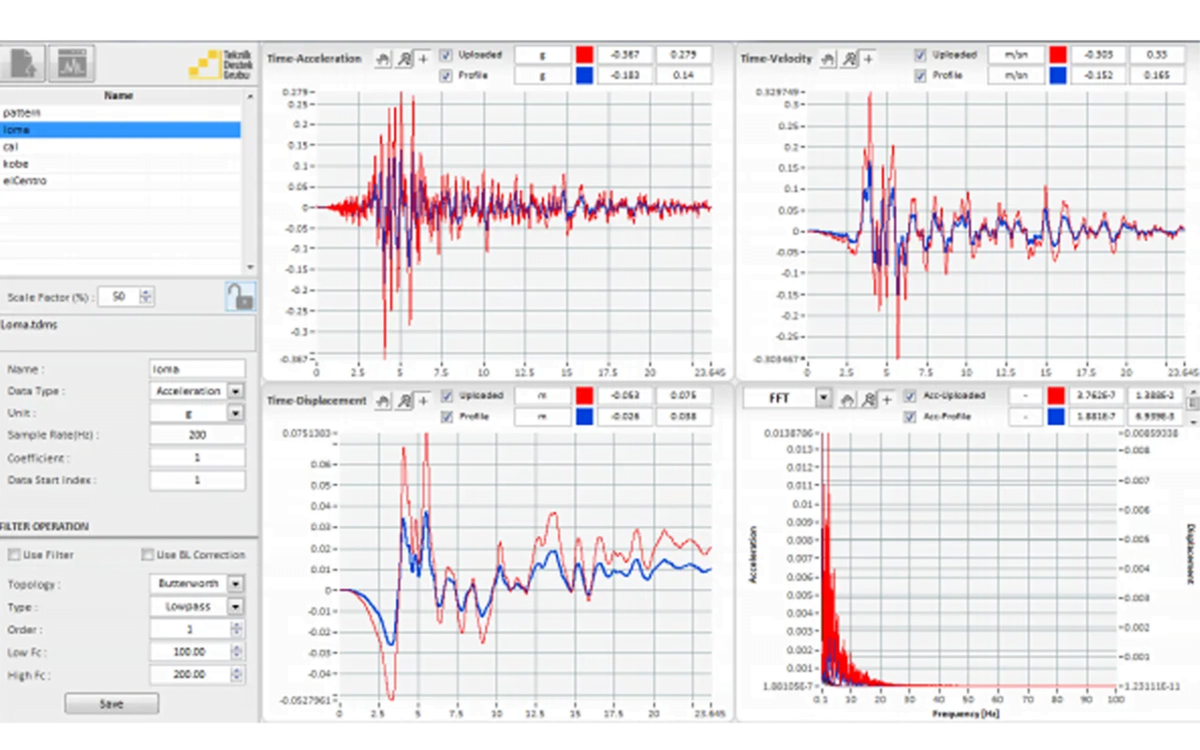

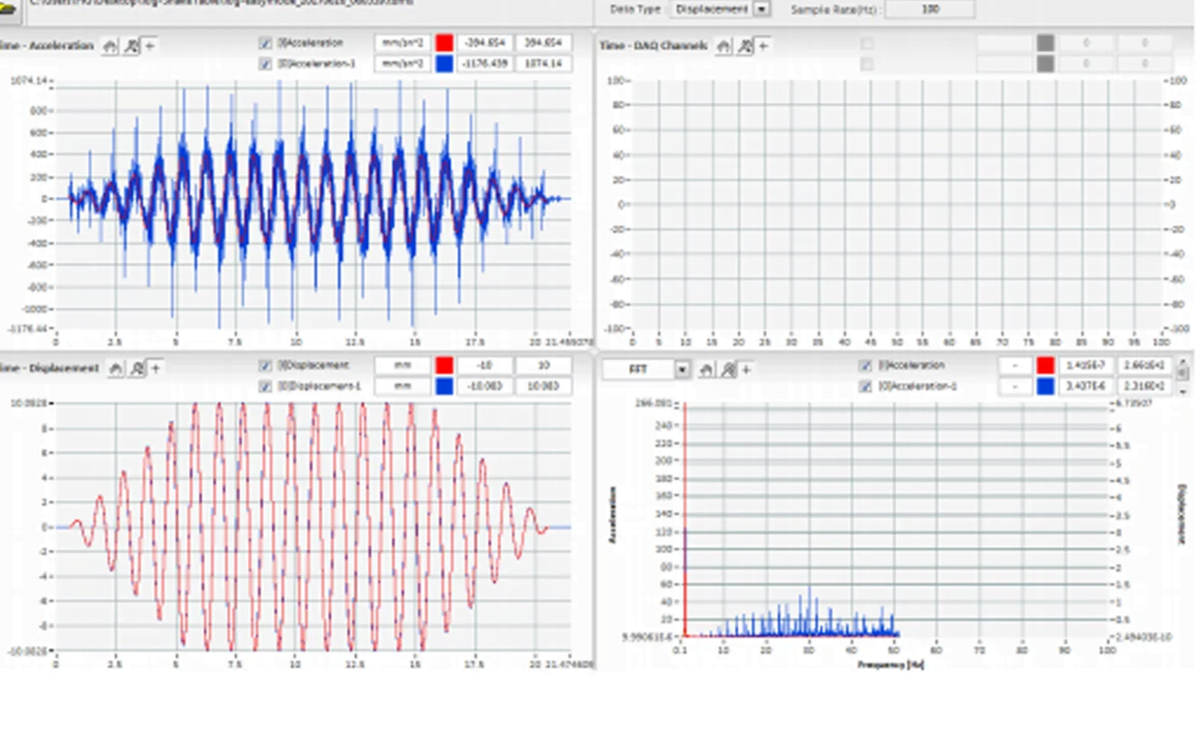

The shaketable comes with a user-friendly software included in the price.

Commonly used in Civil Engineering departments for educational purposes, the ATOM can also be used for structural mechanics, earthquake, soil and geological engineering tests.

Media error: Format(s) not supported or source(s) not found

Download File: https://products.quakelogic.net/wp-content/uploads/2024/02/shaketable-atom.mp4?_=1Media error: Format(s) not supported or source(s) not found

Download File: https://products.quakelogic.net/wp-content/uploads/2024/02/ATOM-shaketable-performance-testing.mp4?_=2EasyTest user-friendly control software included

Shaketable ATOM models available

Answer: A YouTube video is available HERE.

For online training via ZOOM, contact us at support@quakelogic.net for pricing and scheduling information.

Answer: For correct functionality, 220 Volt is needed. We recommend using a portable transformer with a minimum of 500 Watt. We provide a transformer, please contact sales@quakelogic.net for pricing.

Answer: We recommend setting the network configuration as follows:

IP: 192.168.2.5

Subnet mask: 255.255.255.0

Gateway is not important but it can be set to 192.168.2.1

Answer: Assuming all the software is installed properly, if the system does not move even though you click the “Torque” button and if the system does not move even though you click the “Torque” button and Click “Go to zero” in the software, a setting may need to be changed in a file inside the installation folder. Please refer to Section 3.2 of User Manual to change “dioType” in “project.ini” file. The alternatives are “Sinking” and “Sourcing”

After changing this parameter and starting the software again, make sure that the small LCD display on the table read “RUN” after you hit “Torque” button on the software.

When the torque is closed, the screen will read “RDY” and it will turn into “RUN” when the torque is enabled. When it reads “RUN” system will respond to motion commands through the software.